FHWA is promoting Strategic Workforce Development in highway maintenance, construction and operations.

Strategic Workforce Development, an FHWA Every Day Counts (EDC) Round 6 innovative initiative, anticipates collaboration between government agencies, trade organizations, private agencies and communities to prepare individuals for the construction workforce. The demand for workers in highway maintenance, construction and operations is growing, as is the demand for new skill sets required for work with emerging technologies. An important element of this initiative is the recruitment and retention of women and minorities in the construction sector. Through on-the-job training and supportive services program, NJDOT is exploring ways to work with contractors, contracting associations, and unions on shaping their future workforces, including programs aimed at increasing representation of women, minorities, and other disadvantaged populations in the construction and operations workforce.

We spoke with Lori Margolin, the Associate Vice President for Continuing Education and Workforce Development at Hudson County Community College (HCCC) for her insights on workforce development and a new partnership between HCCC and the International Union of Operating Engineers (IUOE) Local 825 that addresses the need to train individuals for today’s jobs in highway construction and operations.

Community Colleges, Programs and Partners

Q. Can you tell us about your role with the college?

HCCC Continuing Education and Workforce Development works with employers to provide training to meet their needs

I am the Associate Vice President for Continuing Education and Workforce Development at Hudson County Community College (HCCC). My department oversees all non-credit programs at the College. We provide educational programs in a wide variety of areas for community residents, training for unemployed and underemployed job seekers, and work directly with employers to provide basic skills and customized training to incumbent workers. We have partnerships with many diverse organizations and take an “entrepreneurial approach” to developing programs and partnerships which provide an alternate pathway for students to obtain credentials and enter a degree program.

Q. Before we delve into your new International Union of Operating Engineers (IUOE) Local 825 program, please tell us, based on your experiences, if there is a lack of awareness among your student body – especially among women and minority students – for jobs/careers in the highway construction industry?

In general, students often lack awareness of careers in many sectors. I have no specific data to cite in highway construction however I am sure it holds true in this industry. Young people and prospective job seekers are not aware of the full-range of available opportunities and/or have false perceptions about jobs in these sectors. For example, they may erroneously assume no post-secondary degree or certification is needed or that they will work in a “dusty workshop” – neither of which may be true.

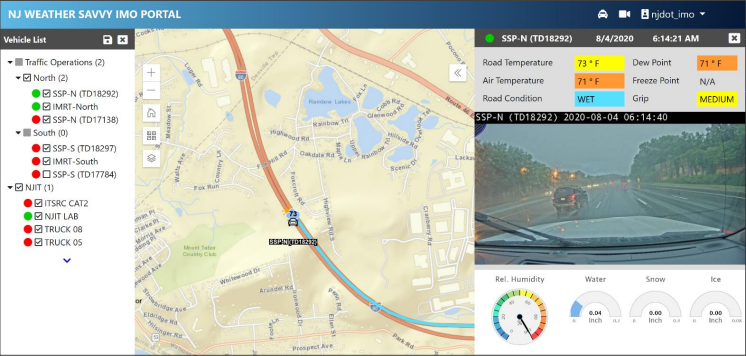

The construction industry is known, historically, as a white male-dominated industry that many do not associate as a sector offering opportunities for persons seeking a post-secondary degree; however, increasingly construction and heavy manufacturing are more automated and need workers with advanced technology skills. The IUOE Local 825 is a union that recognizes this need for workers who are vested with skills to work with new technologies.

For women, minorities, and people with disabilities to be attracted to and successfully retain positions in these fields, both role models and a welcoming work environment are vital. The industry has to examine its policies and practices from top to bottom to address issues of diversity.

Q. Do you know of programs either at HCCC or elsewhere that are building awareness of career opportunities in the highway construction sector?

HCCC offers an Associate degree in Applied Science in Construction Management, which is part of our STEM (Science, Technology, Engineering and Math) division. The program has experienced double-digit enrollment growth due to factors including the recent November 2021 passage of the federal Infrastructure bill. Rowan University offers a Bachelor’s degree in Construction Management and there may be others.

HCCC and Rowan College of South Jersey will be leading the Construction Center for Workforce Innovation as part of the NJ Pathways to Career Opportunities program, which is a joint initiative of the NJ Community College Consortium for Workforce and Economic Development and the NJ Business and Industry Association. We are looking at expanding the pathways in construction, creating new partnerships with K-12 and 4-year colleges and universities, and expanding the dual education program to include additional partners. Whatever new curricula are developed via the initiative will be shared statewide.

Q. Several commonly cited roadblocks to entry into the construction sector particularly for women and minority candidates include transportation issues and childcare. Have your students encountered these or other obstacles? Do you see a role for NJ community colleges in helping to reduce barriers for women and minorities in entering the highway construction trades?

Both transportation and childcare are obstacles to entry and retention in construction and other sectors. For example, if a person’s vehicle is not reliable, how are they going to access the job site? For some job seekers, the costs of child care can be a large proportion of their income.

The ongoing COVID-19 pandemic has created additional challenges, as some job seekers are concerned with taking a job where they may be exposed to the virus and bring it home to older or immune-compromised family members. In some cases, prospective workers must care for family members impacted by COVID-19 and balance demands related to their children’s home school instruction. The number of female employees in many sectors has decreased since the onset of the pandemic because many of these familial responsibilities fall to women. Overall, these constraints are influencing the types of jobs candidates are pursuing.

I see a role for community colleges in helping to reduce barriers for women and minorities in entering highway construction and other sectors. Community colleges serve students from highly diverse backgrounds who bring a variety of experiences to their classes. Community colleges serve more first-generation, part-time, nontraditional age, low-income, minority, and female students than any other type of public higher education institution. We focus on economic mobility and preparing students to launch successful careers and earn family-sustaining wages.

The pandemic has exacerbated issues that students and job seekers face, such as childcare and transportation. Many HCCC students have non-academic needs including food insecurity and face emergencies, such as car repair, that are beyond their financial means to resolve independently. To help address these issues, HCCC has expanded student supports, as the college considers itself part of the community it serves. The Hudson Helps program provides a food pantry, emergency grants, and has paid almost $5 million in outstanding debts for students during the pandemic.

While these issues are long-standing, if the community works together I believe we can effectively address them.

Q. Your department partners closely with the business community, offering a variety of programs and resources to help meet their workforce needs. Do you also partner with any community-based organizations to support any of your apprenticeship or other programs? If yes, do any of these organizations specifically focus on supporting women and minorities in the workforc

There are many community-based organizations and programs that support students in preparing for careers. Several of our partners in Hudson County are Women Rising, the Statewide Hispanic Chamber of Commerce of New Jersey and Year Up. Year Up primarily works with minority and low-income students to introduce them to careers in business, finance, and technology, and they have an office on our campus. We partner with many others as well.

International Union of Operating Engineers (IUOE) Program

Q. With HCCC as a registered apprenticeship sponsor with USDOL, do you have apprenticeship programs in place focused on advanced manufacturing, healthcare and -- now with the IUOE Program -- operating engineering?

HCCC is a Registered Apprenticeship sponsor and currently has an advanced manufacturing employer, Eastern Millwork, and one hospitality employer, Skopos Hospitality. In addition we have agreements with many healthcare providers to train apprentices. We are a partner on an application for a culinary Pre-Apprenticeship in Career Education (PACE) training grants through the NJ Department of Labor and Workforce Development (NJDOL).

Many employers are hesitant to pursue apprenticeships because they do not understand what an apprenticeship entails, and the benefits that an apprenticeship could offer to both employers and participants. In fact, many confuse internships with apprenticeships, with one distinction among the two being that apprenticeship participants are hired as employees, although there are other differences as well.

We have an agreement with the International Union of Operating Engineers (IUOE) Local 825 to articulate up to 30 credits towards an Associate degree (60 credits). Apprentices with IUOE Local 825 can pursue an Associate degree while completing the apprenticeship program.

Q. Can you please outline the basics of the International Union of Operating Engineers (IUOE) program?

HCCC and the IUOE are training workers for the construction industry, including highway construction.

The IUOE program is technically an advanced manufacturing initiative that is supported by a NJ PLACE 2.0 grant. This innovative program was established in November 2021 through an articulation agreement between HCCC and IUOE Local 825 and gives students the opportunity to be dually enrolled in the union apprenticeship program and HCCC, where they will earn an Associate of Applied Science in Technical Studies degree after they complete 60 credits.

Participants will earn 30 credits from on-the-job training and education provided by the union, and are scheduled to earn the other 30 credits from HCCC over five semesters. They will be attending part-time, taking two classes per semester and earning six credits per semester on average.

Q, What are the main goals for the IUOE program?

The main goals for the NJ PLACE 2.0 grant are promoting equality of opportunity, upward economic mobility, and economic fairness.

Q. What makes the IUOE program particularly innovative?

The program is innovative and beneficial because it provides students with the unique, time-saving opportunity to pursue their journeyworker status simultaneously with earning their Associate degree. The program is designed so that students earn credit for experience outside the classroom, and college classes enhance what they are learning at work. There are no out of pocket expenses for the students since costs are covered by the grant and IUOE Local 825.

The degree will give students additional options and pathways. Future operators will need to master heavy equipment and also understand and work with the technology behind it.

Q. How is program implementation going so far? Approximately how many students are currently enrolled?

The program will start in the spring 2022 semester on January 21, 2022. Thirty students of diverse backgrounds from throughout the state were accepted for enrollment. The students had to commit to both components of the program, earning the Associate degree and to the apprenticeship program. Hundreds of prospective applicants applied in the first 20 minutes that the online application portal opened.

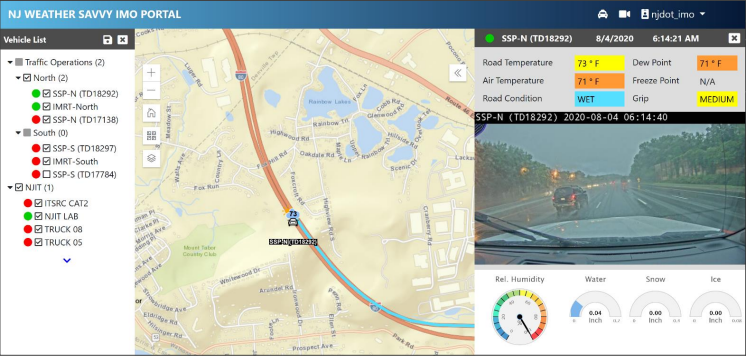

All HCCC instruction is virtual, although the orientation was held in-person on-campus. The virtual modality allows students who reside throughout the state to easily attend. The IUOE Local 825 members are trained in real-world facilities on the latest models of equipment, including those with the newest technology and GPS systems. The state-of-the-art training facility located in central New Jersey near Exit 8A of the NJ Turnpike, has a total area of nearly 60 acres, with more than 90 pieces of equipment, simulators and instrumentation.

Q. What career paths and industries will program graduates typically pursue? Are construction jobs a focus of the program? Has there been any discussion about preparing workers in the highway construction trades?

Local 825 Operating Engineers are highly trained and experienced heavy equipment operators, mechanics, and surveyors who offer unsurpassed productivity to contractors throughout New Jersey and five counties in New York’s Hudson Valley

Q. We read that the IUOE program is one of two in the state. Are you aware of the other program?

HCCC is the only community college in New Jersey offering this program. Thomas Edison State University is another institution with a NJ PLACE 2.0 grant.

Q. Do you see this as an ongoing program or dependent on grant funding that might not be forthcoming in future years?

Currently, the grant covers half the tuition and fees for students and the union covers the remaining portion. Both HCCC and the IUOE Local 825 are committed to the program. Our interests and missions align and I see the program continuing. The program itself enables students to train with and learn current technology, and improves readiness for current and future career pathways.

Looking Ahead

Q. What strategies should be pursued to encourage more NJ community college students to consider a career in the construction industry? Who should be leading or involved in those efforts?

Increasing awareness of the career pathways available in the construction industry would be helpful in encouraging more NJ community college students to consider this option. New Jersey's Community Colleges and New Jersey Business and Industry Association are leading a collaborative effort to address the rapidly changing needs of employers and providing students and workers with the career pathways they need to be successful. As a key component of this coordinated workforce preparation effort, the NJ Council of County Colleges has launched 10 Centers of Workforce Innovation specifically focused on building pathways to serve the learning lifespan of students and workers. The Centers are clustered in four industries, Healthcare, Technology and Innovation, Infrastructure and Energy, and Manufacturing and Supply Chain Management. HCCC is the administrative lead on the Construction Center of Workforce Innovation (part of the Infrastructure industry) and is partnered with Rowan College of South Jersey. There was a statewide convening on January 19th to kick off the planning phase of the work.

Q. Through their on-the-job training and supportive services program, NJDOT is exploring ways to work with contractors, contracting associations, and unions on shaping their future workforces, by focusing on training and recruitment programs aimed at women, minorities, and other disadvantaged populations. Do you have any thoughts about how NJDOT might pursue this goal?

New Jersey’s 18 community colleges serve over 300,000 people in non-credit, credit, and workforce development courses

NJDOT Human Resources staff and/or senior leadership should partner with NJ’s community colleges so we can familiarize NJDOT with opportunities to align in-demand skills for degree programs and develop customized non-credit programs and training for their workforce. Community colleges can uptrain or re-train the NJDOT workforce to succeed in new or revamped roles. HCCC and other community colleges can also work with NJDOT to help the department achieve increased workforce representation among females and minorities. NJDOT can engage in conversations with educators and let us know what skills the NJDOT workforce needs so that we can help address skill gaps. There are 18 community colleges in the state; NJDOT could opt to reach out to the NJ Council of County Colleges to start the conversation.

NJDOT workers and others may want to consider taking advantage of the Community College Opportunity Grant initiative. New Jersey students enrolled in any one of the State’s 18 county colleges may be eligible for tuition-free college. Students who are enrolled in at least 6 credits per semester and who have an adjusted gross income of $0-$65,000 will be considered for this state grant.

Resources

Federal Highway Administration, Every Day Counts Round 6, Strategic Workforce Development. https://www.fhwa.dot.gov/innovation/everydaycounts/edc_6/strategic_workforce_development.cfm

Hudson County Community College, Workforce Development. https://www.hccc.edu/programs-courses/workforce-development/index.html

International Union of Operating Engineers, Local 825. http://www.iuoe825.org/

NJ Community College Consortium for Workforce and Economic Development. https://njworkforce.org

NJ Department of Labor, NJ PLACE 2.0 Grants. https://www.nj.gov/labor/lwdhome/press/2020/20200131_njplace.shtml

NJ Department of Labor, Office of Apprenticeships. https://www.nj.gov/labor/career-services/apprenticeship/

NJ Pathways to Career Opportunities. https://njpathways.org/centers-of-workforce-innovation/