The NJ State Transportation Innovation Council (NJ STIC) gathered virtually for its third Triannual Meeting of 2025 on December 10. The Core Innovation Area (CIA) Teams presented updates on progress towards the Every Day Counts Round 7 (EDC-7) goals and Konstantinos Kyros, Operations Analyst for Mobility Planning and Research at NJDOT, delivered the meeting’s featured presentation, Advancing Innovation: NJDOT Mobility Research and Planning.

Welcome Remarks

Eric Powers, Assistant Commissioner at NJDOT, provided the welcoming remarks for the STIC meeting. He reviewed the meeting agenda, highlighted the importance of delivering projects more quickly and more cost-effectively amid uncertainty surrounding the federal fiscal bill, and expressed optimism for NJDOT’s innovative initiatives.

FHWA Updates

Christopher Paige, Innovation Coordinator and Community Planner at the FHWA NJ Division Office, provided updates and thanked attendees for submitting STIC Incentive project reports in on-time. Mr. Paige reported that the federal government awarded a $97,147 STIC Incentive Grant to the New Jersey Sports and Exposition Authority to optimize adaptive system performance and improve travel time using the ATSPM Module. These funds will support New Jersey’s preparations for the upcoming 2026 FIFA World Cup.

He also noted that the FHWA Division Office has not yet received updates regarding Round 8 of Every Day Counts (EDC-8) and will follow up with stakeholders once more information becomes available.

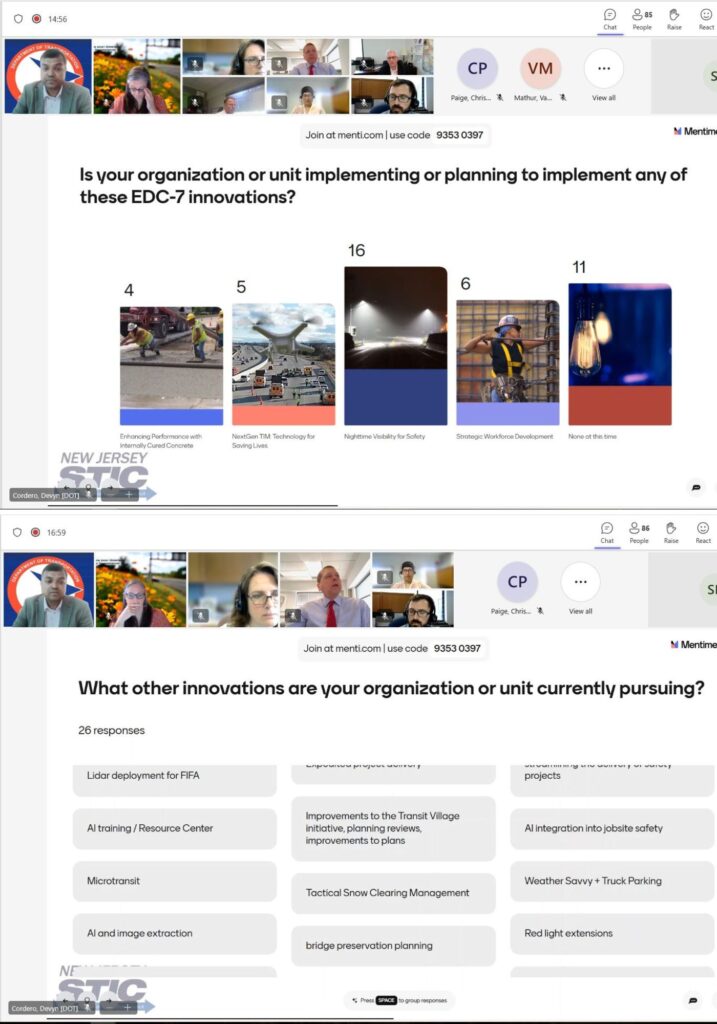

Core Innovation Areas (CIA) Updates

The CIA Teams provided updates on progress toward deployment goals for their respective innovation efforts. Representatives from NJDOT and FHWA discussed EDC-7 initiatives organized under the five CIA teams: Safety, Planning and Environment, Infrastructure Preservation, Mobility and Operations, and Organizational Support and Improvement. Each team outlined current projects, highlighting implementation efforts, key achievements, and challenges. A summary of each team’s update follows:

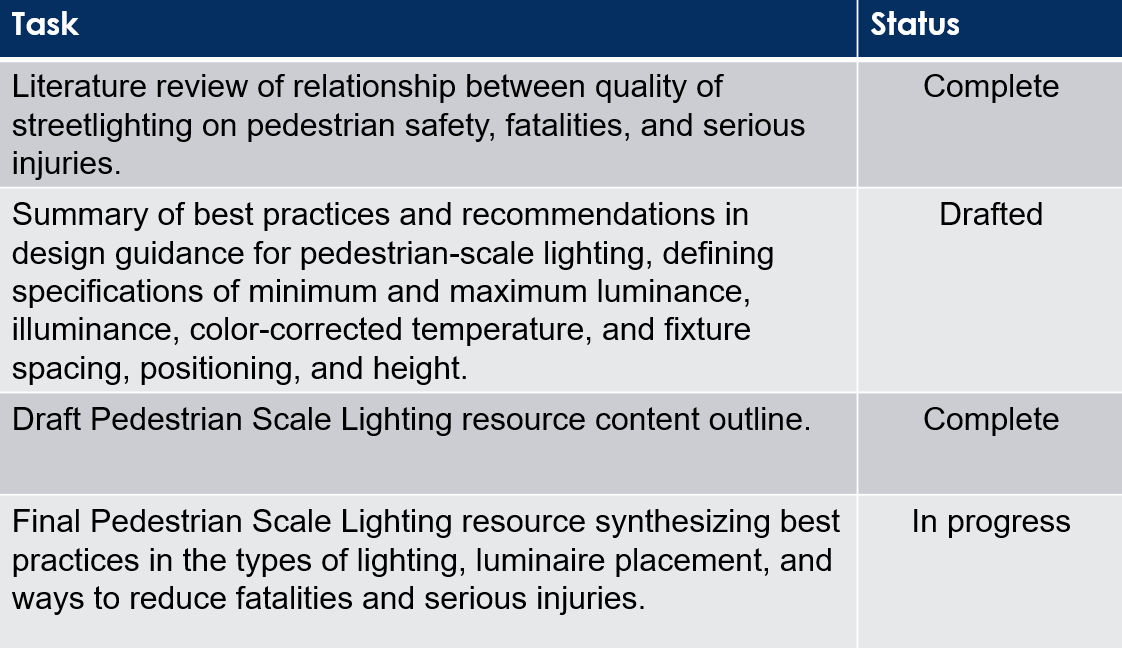

Safety

Pedestrian Scale Lighting Research & Guide. Researchers from the Alan M. Voorhees Transportation Center (VTC) at Rutgers University, in partnership with Rowan University, continue to edit and revise a draft pedestrian-scale lighting resource. The guide is intended to help communities identify, scope, and evaluate safety and community needs prior to implementing best practices in pedestrian-scale lighting design. The project team is incorporating subject matter experts (SME) comments and finalizing the resource.

Nighttime Visibility for Safety. In collaboration with other NJDOT review units, the Division of Traffic Engineering is finalizing design details for traffic signal poles and mast arms in compliance with the 2015 AASHTO LRFD requirements for signalized intersection. Design improvements include enhanced integration of backplates with retroreflective tape on signal indications.

Planning and Environment

Congestion Mitigation and Air Quality Improvement Program (CMAQ) and Carbon Reduction Program (CRP). NJDOT has advanced initiatives designed to ease congestion, enhance air quality, and support the adoption of low-emission technologies. CMAQ priorities include public transit expansion, intersection improvements, intelligent transportation systems, and electric vehicle incentives. CRP efforts emphasize battery-electric buses, Complete Streets projects, and the transition of municipal fleets to greener technologies. Upcoming goals include accelerating project implementation, deploying AI-based traffic management strategies, and expanding collaboration with MPOs and NJDEP.

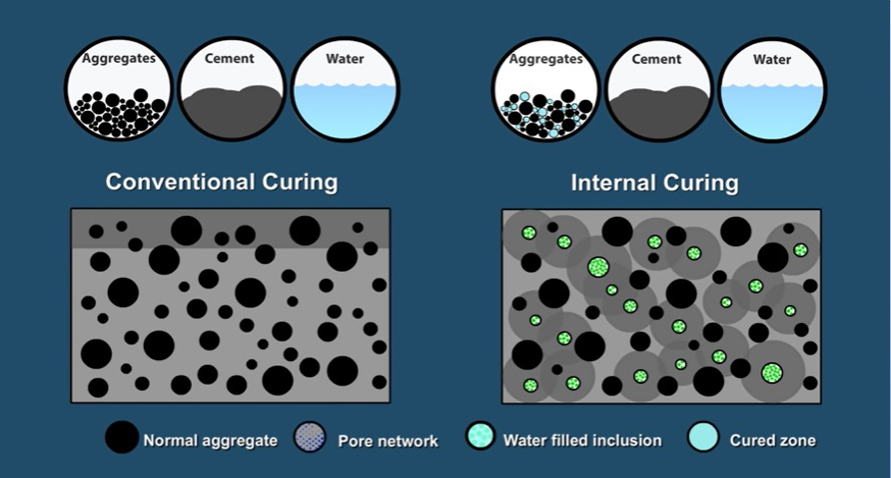

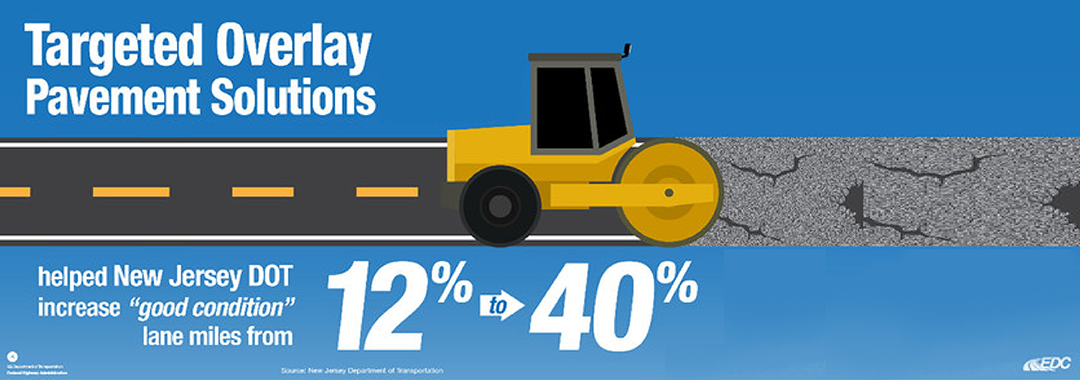

Infrastructure Preservation

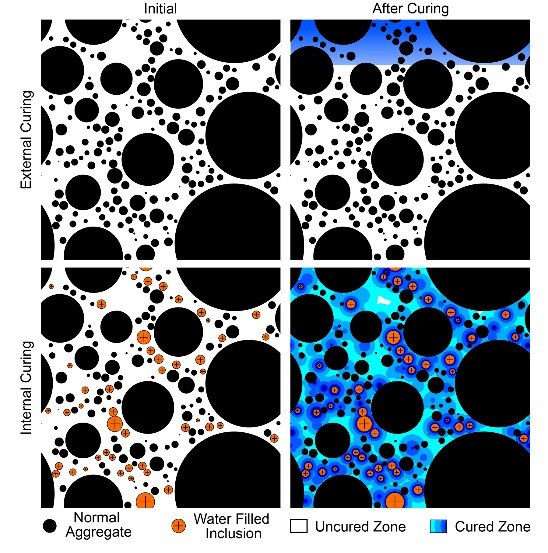

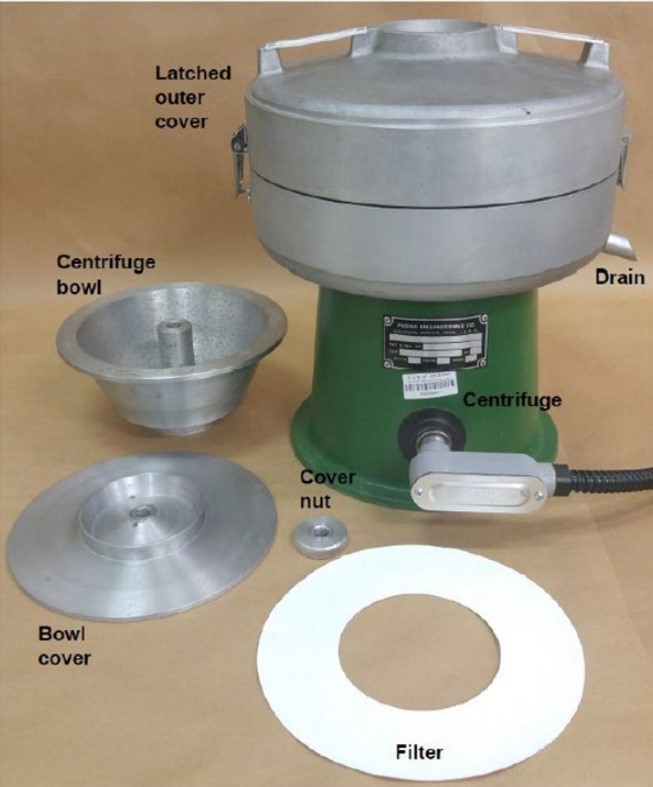

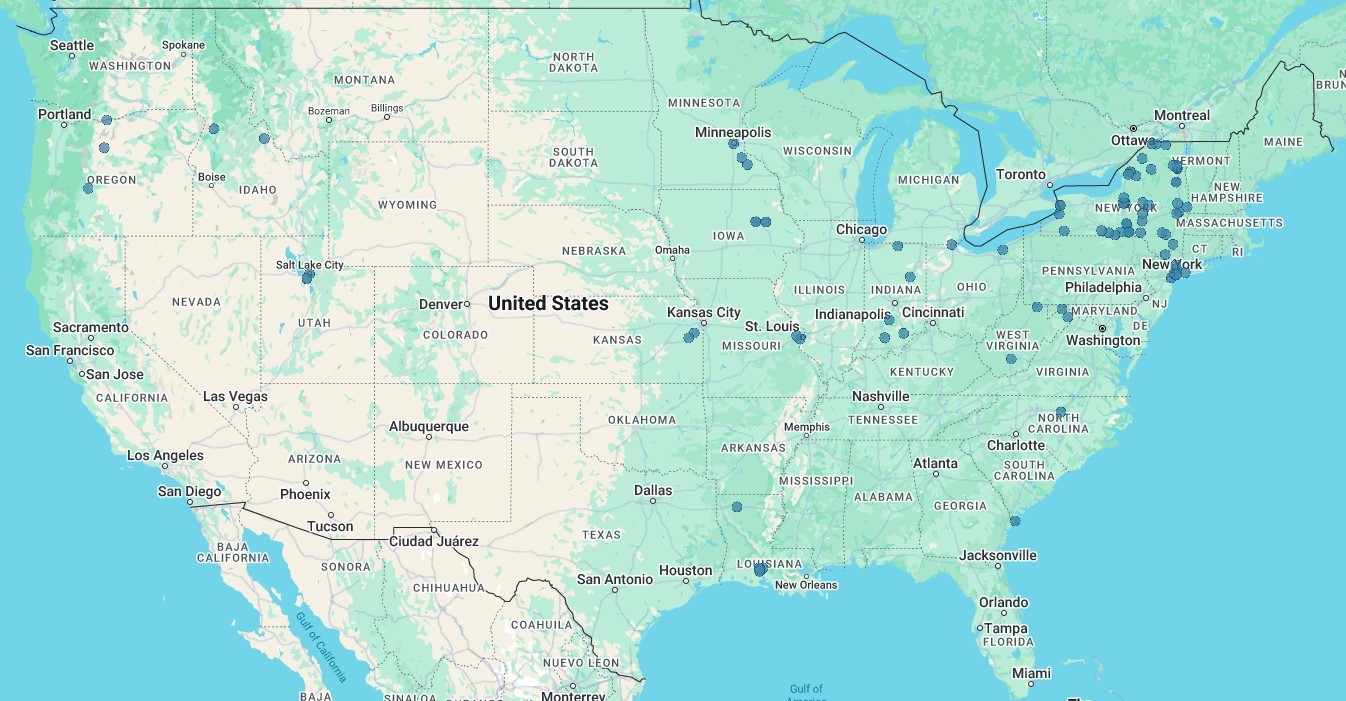

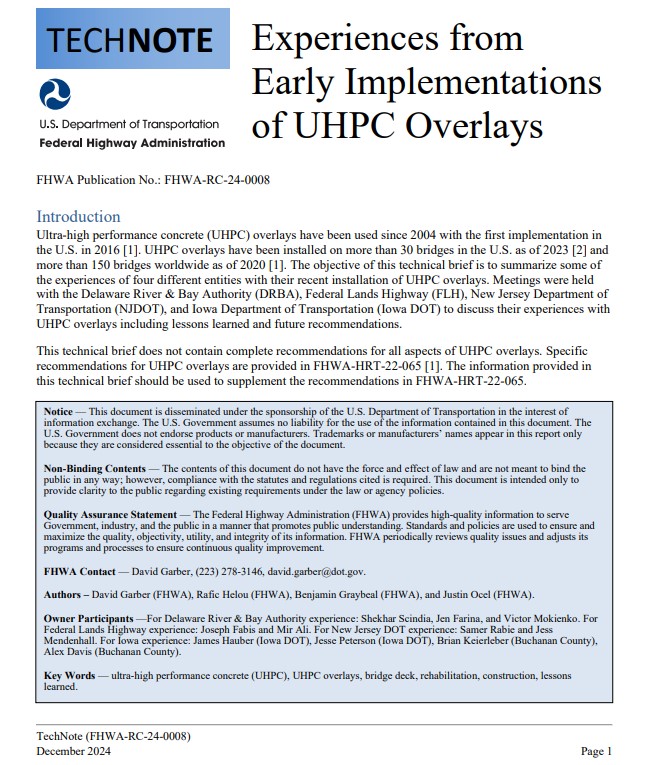

Enhancing Performance with Internally Cured Concrete (EPIC2). The team has awarded contracts to two bridge projects using HPIC bridge decks: CR507 (Maple Ave), Bridge Over Rt. 208; and CR 650 (Hanover Ave), Bridge Over I287. NJDOT will also host a workshop on the fundamentals on internal curing (January 2026), and a regional materials engineers and technicians training (February 2026).

Next quarter, the CIA Team plans to monitor construction of the HPIC-cast trail slabs for the bridge at North Munn Avenue. A key challenge has been reluctance among concrete suppliers to produce HPIC due to concerns over stringent NJDOT specifications. To address this issue, NJDOT will launch a strategic outreach plan that includes meetings and technical discussions between NJDOT SMEs and industry stakeholders.

Mobility and Operations

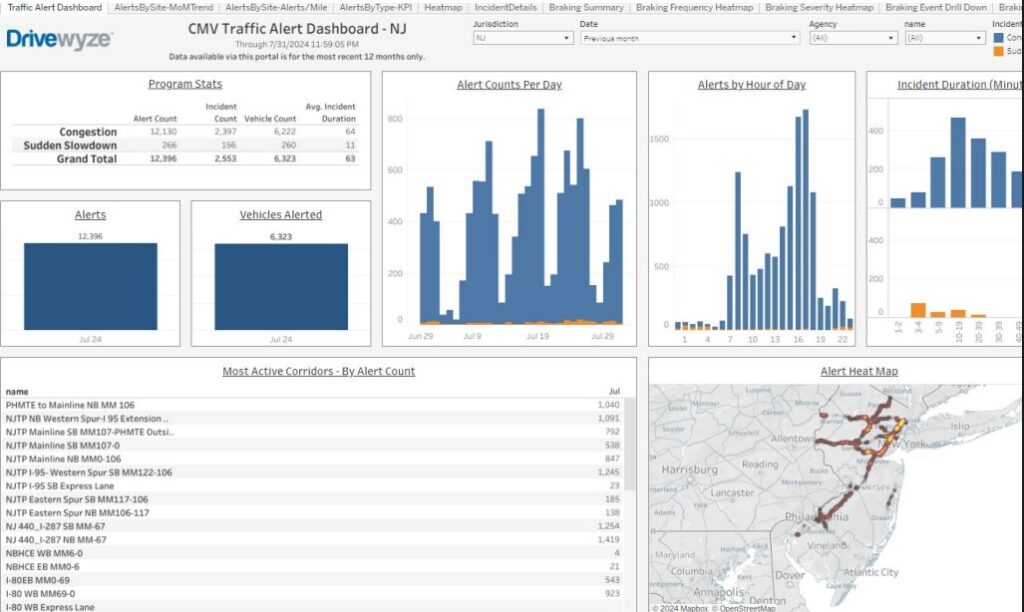

Traffic Incident Management (TIM) Technology. NJDOT has deployed TIM technology across numerous projects and initiatives, including installing light towers on NJDOT Incident Management Response Trucks (IMRT), using LED flares at incident sites, and partnering with Drivewyze to provide real-time notifications to truck drivers about stopped queues and slowdowns. The Mobility and Operations Team plans to integrate innovative activities into the NJDOT Intelligent Transportation System/Traffic Operations work programs. An additional initiative includes expanding TIM Emergency Responder Training. More information is available at njtim.org/NJTIM.

Organizational Support & Improvement

Strategic Workforce Development. The initiative remains in the development stage. Although FHWA has approved funding, disbursement delays have occurred due to funding pauses and other constraints. NJDOT is working with its Division of Procurement and has partnered with NJDOL’s Workforce Development Services to advance training and apprenticeship preparation programs.

In August 2025, NJDOT met with the Contractor Compliance Unit to discuss union engagement, apprenticeship programs, workforce aging, and strategies to increase participation. The team plans to host a dual open house in early 2026 for individuals interested in working on NJDOT construction projects.

Feature Presentation: Advancing Innovation–NJDOT Mobility Research and Planning

Konstantinos Kyros, Operations Analyst for Mobility Planning and Research at NJDOT, delivered the meeting’s feature presentation, outlining projects and initiatives led by the Mobility and Operations CIA Team.

Projects discussed include:

- Weather Savvy Roads Pilot

- Groundcast

- Truck Parking Pilot

- Deployment of new technologies, including Streetlight Insight, HAAS – Digital Alerts, and LiDAR

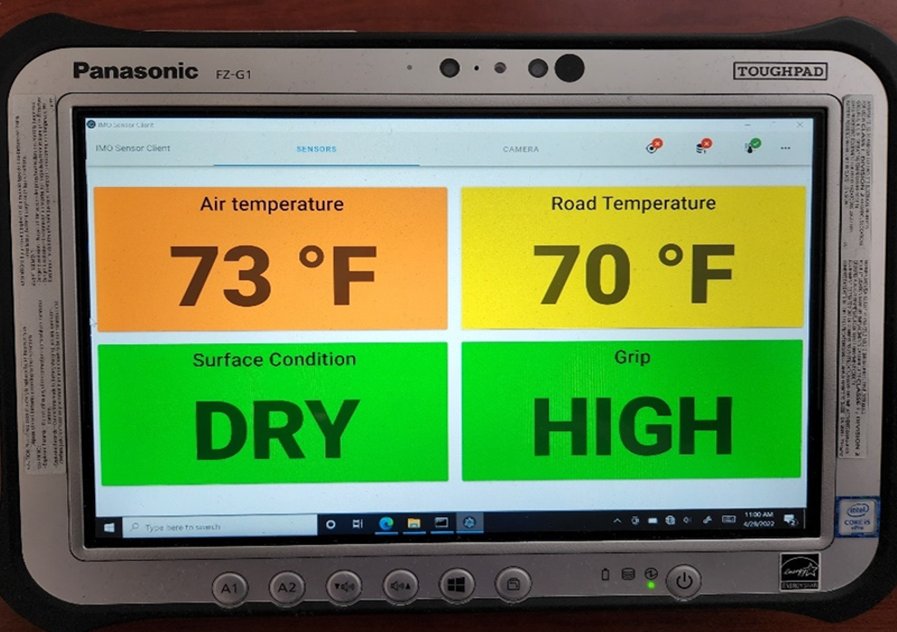

Weather Savvy

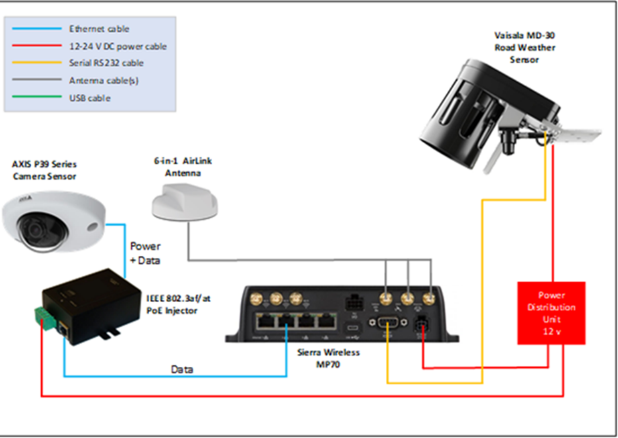

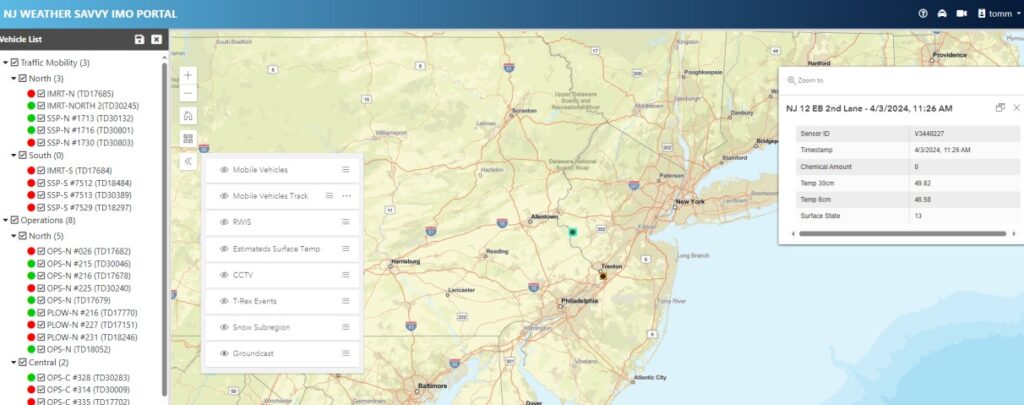

NJDOT has deployed Internet of Things (IoT) and Connected Vehicle (CV) technology on a fleet of state vehicles to support real-time road weather management. Sensors collect data during daily operations, with a focus on snowplows that remain active during weather events. Installations began in December 2023 on 24 vehicles and have expanded to 45, evenly distributed statewide.

The system uses Vaisala MB30 road weather sensors to capture road surface condition and temperature, air temperature and humidity, and roadway grip. Data are visualized on tablets and an online portal to support analysis and decision-making.

Recent upgrades improved durability and reliability issues by relocating components into a protected plexiglass junction box and rewiring the system to allow direct data transfer between the modem and data cloud, reducing points of failure. The platform also includes live camera feeds of road conditions, with a transition underway from bullet to dome cameras for greater stability.

Groundcast

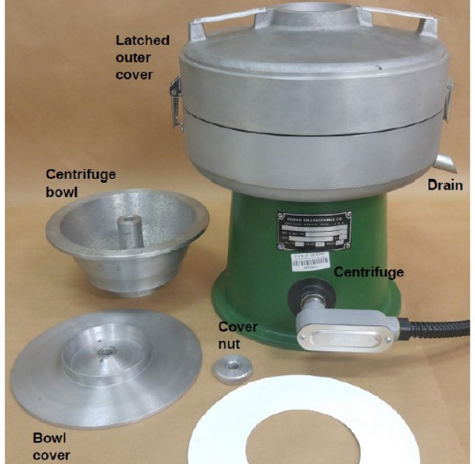

NJDOT is piloting Vaisala Groundcast weather sensors that measure surface temperature, surface condition, and the presence of treatment materials on the roadway. The sensors use internal batteries with a three-year lifespan and transmit data via cellular communication. Installations have been completed at NJ-12 westbound MP 0.4, NJ-12 eastbound MP 1.5, NJ-23 northbound MP 47.7, and I-295 northbound MP 57.6.

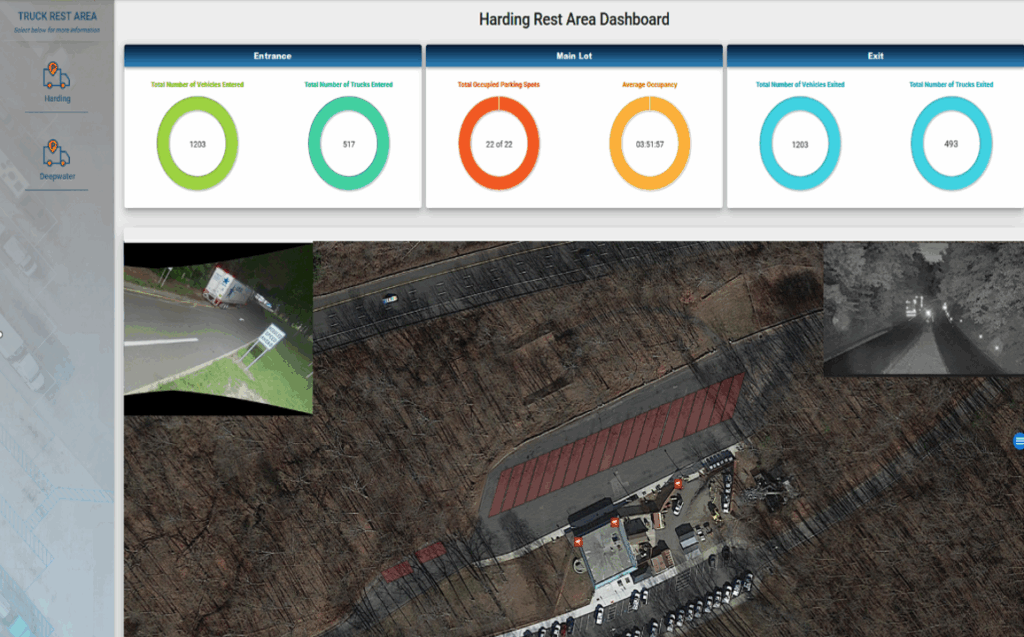

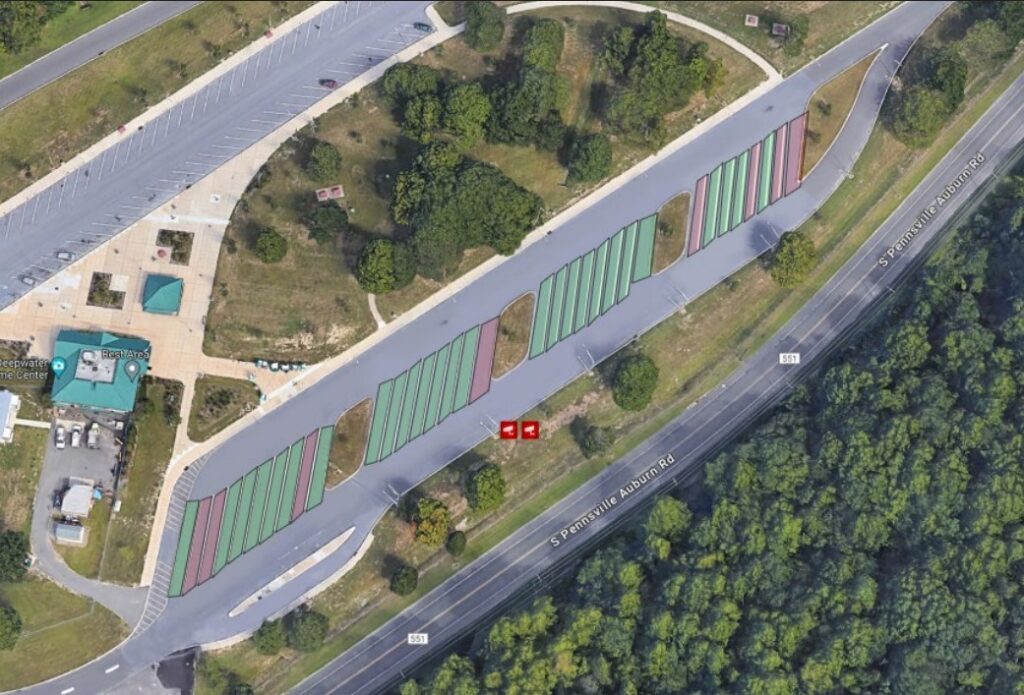

Truck Parking Pilot

NJDOT launched its truck parking pilot in 2021 at the Harding Rest Area to provide truck drivers with real-time information on available parking spaces and reduce unsafe parking practices. The program expanded to the Deepwater Rest Area in Carney’s Point in summer 2023, and NJDOT began installing sensors at the Knowlton Rest Area in December 2025.

Parking availability is detected using CCTV cameras and in-pavement micro-radar sensors. Portable dynamic message signs (DMS) placed approximately five miles from Harding along I-287 and I-78 alert drivers of the number of available spaces.

At Harding, the system includes two traffic microwave sensors, nine CCTV cameras, and 44 in-pavement sensors. The Deepwater site includes two traffic microwave sensors, one CCTV camera, and 68 in-pavement sensors. The Knowlton site includes two traffic microwave sensors, four CCTV cameras, and 46 in-pavement sensors. A truck parking dashboard provides systemwide monitoring, displaying total vehicles counts, occupied spaces, average occupancy, and live CCTV feeds.

Other Technology

Other initiatives include partnering with StreetLight Insight, a web-based platform that uses connected device and IoT data to measure vehicle, transit, bicycle, and pedestrian activity. NJDOT has also deployed HAAS Digital Alerts in all Safety Service Patrol (SSP) vehicles to monitor vehicle status and location and to help motorists identify SSPs through navigation apps, with plans to expand deployment to IMRTs. Additionally, NJDOT has installed LiDAR on one SSP vehicle to remotely measure distances and monitor compliance with the Move Over law.

Announcements and Reminders

Submit Your Research or Innovative Idea!

Share your innovative, research, or market-ready ideas using one of the forms available here.

Next Meeting

The NJ STIC 1st Triannual Meeting of 2026 has not yet been scheduled. The Planning and Environment CIA Team will deliver the feature presentation. Giri Venkiteela, Innovation Officer at NJDOT, will contact stakeholders once a date is selected.

A recording of the NJ STIC 2025 3rd Triannual Meeting is available here. The meeting’s presentation slides are available below.