Enhancing Performance with Internally Cured Concrete (EPIC2) is a model innovation in the latest round of the FHWA’s Every Day Counts Program (EDC-7). EPIC2 is recognized as an innovative new technique that can be used to extend the life of concrete bridges and roads. Internal curing increases concrete’s resistance to early cracking, allowing the production of higher-performance concretes that may last more than 75 years.

This Q&A article has been prepared following an interview and follow-up correspondence with Samer Rabie and Jess Mendenhall of the New Jersey Department of Transportation. The Q&A interview has been condensed and edited for clarity.

Q. What is Internally Cured Concrete, and how does it differ from traditional concrete?

A common issue with high performance concrete (HPC) bridge decks is that soon after the curing is done, they develop fine shrinkage cracks spread throughout the deck. Even this fine cracking can reduce the service life. In the past, we have used crack sealing materials as a mitigation effort, but when we learned about internally cured concrete, we shifted our focus to see if we could adopt it in New Jersey.

Autogenous or chemical shrinkage is specific to HPC concrete, where the w/c ratio is less than 0.42. It is due to self-desiccation, which is water consumed by the cementitious materials after setting, and that is one where internal curing can help.

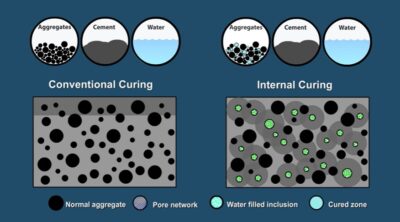

There are multiple methods to implement internal curing. The method that we are considering involves modifying a conventional concrete mixture to an internally cured concrete mixture by replacing a portion of the fine aggregate (sand) with lightweight fine aggregate. This lightweight fine aggregate (LWFA) is saturated with internal curing water, typically estimated at 7lbs of water for every 100lbs of cementitious materials used in the mixture. Next, the amount of LWA required for this amount of internal curing water is determined based on the mass of the internal curing water and the absorption of the LWFA. Once the total volume and mass of lightweight aggregate are determined, the volume (and mass) of the fine lightweight aggregate are adjusted so that the volume of LWFA and fine aggregate in the internally cured mixture is equal to the volume of the fine aggregate in the original mixture.

The LWFA will provide internal curing water within the concrete mix during curing, and prevent a condition that occurs in low W/CM ratio systems where the capillary water within the concrete matrix pores will be consumed without complete cement hydration, which can lead to cracking of the concrete matrix.

Q. How does Internally Cured Concrete improve performance?

Internal curing improves the performance of concrete by increasing the reaction of the cementitious materials and reducing internal stresses that typically develop in high-cementitious content mixtures if insufficient internal curing water is present. However, in addition to conventional curing which supplies water from the surface of concrete, internal curing provides curing water from the aggregates within the concrete. This provides a source of moisture from inside the concrete mixture, improving its resistance to cracking and overall durability.

Q. Are there any limitations on the use of internally cured concrete?

Internal curing is extremely versatile and can generally be used anywhere traditional concrete is used. Most of the process is the same, and aggregates can be pre-saturated as needed. It follows the norms of industrial concrete production, making it accessible to any producer already familiar with the state of practice. Most of the implementation process is similar to conventional concrete.

Q. What New Jersey sites were picked for use in internally cured concrete, and why?

We started with a list of all of our bridge projects, specifically projects that needed deck replacement and superstructure replacement. We then further targeted projects that allowed us to focus on implementation and quick delivery time rather than constructability and other additional challenges. We looked at projects with straightforward staging and geometry and prioritized projects with twin bridges (for example, northbound and southbound). This would allow us to do one bridge with traditional HPC and the other with internally cured HPC, providing us with an excellent controlled opportunity to study and compare the results.

Various sites have been screened throughout the state. Currently, eight bridges are under consideration, with a project scope of work of deck and superstructure replacement. The rationale included the project scope of work, CIP deck slabs, project schedule, staging constraints, and avoiding heavily skewed bridges.

Q. Have any life cycle cost analyses been performed?

We have not prepared one ourselves, but we do plan on doing so in the future. First, we will need to get these projects out to construction and get actual cost data. We’re expecting higher upfront costs, but if cracking is reduced then the life cycle costs and future maintenance and reconstruction needs can be significantly reduced.

Q. In what ways do you think people can be better educated on the implementation of EPIC2?

We have presented to many of our stakeholders in our capital program to discuss the topic, and now that it is an EDC initiative, decision makers are acknowledging its value. The Federal Highway Administration is also planning on conducting workshops and peer exchanges between contractors, concrete suppliers, and other agencies like New York State DOT, which have already done this. All of these are extremely valuable.

We first heard about internally cured concrete during a peer exchange in 2021 with the New York State DOT. It was under the banner of EDC-6, and they took us out on several bridges where we noted that they have significantly reduced the typical shrinkage cracking that is common with High Performance Concrete. So that was an eye opening experience for us, and I know it would be valuable to others. The fact that it is now its own initiative in EDC-7 helps facilitate implementation.

Q. Is special training needed for contractors to work with internally cured concrete?

From our research and experience with other agencies, the finishing should not be significantly different from conventional HPC. The process at that point will be almost identical to placing traditional concrete, so there won’t be any learning curve or time spent on getting workers to learn how to deal with a new material. In fact, most contractors say that the mixture is easier to work due to improved pumpability as the material is quite smooth. I think the crucial step will be to coordinate with concrete production plants that are creating the mixes.

Q. Where else has internally cured concrete been implemented?

So far it has been used in bridge decks in many states, including New York, Ohio, and North Carolina, among others. It has also been used in pavement and pavements in Kansas, Texas and Michigan.

Q. What is the future of internally cured concrete in New Jersey?

We hope these projects will be successful, and that our current crop of projects will result in some valuable lessons learned. In the long term, I believe the goal would be that all of the bridge decks would use an internally cured mixture. I can also see this being used for patching and deck repair jobs. But ultimately, the goal would be for this to become the new standard for bridge decks across the state.

Resources

Federal Highway Administration. 2023 Internally Curing Concrete Produces EPIC2 Results. https://www.fhwa.dot.gov/innovation/innovator/issue98/page_01.html

Federal Highway Administration. 2023. Enhancing Performance with Internally Cured Concrete. https://www.fhwa.dot.gov/innovation/everydaycounts/edc_7/docs/EDC-7FactsheetEPIC2.pdf

Federal Highway Administration. (2018, June). Concrete Clips: Internal Curing. https://www.youtube.com/watch?v=b6WREFmacaM

New York State DOT Standard Specifications (2021). Standard Specifications. New York State DOT. https://www.dot.ny.gov/main/business-center/engineering/specifications/busi-e-standards-usc/usc-repository/2021_9_specs_usc_vol2.pdf

National Concrete Pavement Technology Center Internal Curing Resources. (2022). Internal Curing. Iowa State University. https://cptechcenter.org/internal-curing/

Internal Curing. (2020). Oregon State University. https://engineering.oregonstate.edu/CCE/research/asphalt-materials-performance-lab/materials-research-concrete-materials/Internal-Curing

Pacheco, Jose. (2021, October). USDOT Workshop Report, Bureau of Transportation Statistics. Wisconsin Department of Transportation. https://rosap.ntl.bts.gov/view/dot/62607

Weiss, Joseph. (2015, July). Internal Curing Technical Brief. Federal Highway Administration. https://www.fhwa.dot.gov/pavement/concrete/pubs/hif16006.pdf