The Safe System Approach (SSA) is a transformative framework for roadway safety that aims to eliminate all fatalities and serious injuries on our transportation network. Adopted by New Jersey Department of Transportation (NJDOT) as part of its commitment to reach zero roadway deaths by 2040, SSA shifts the focus from individual behavior to system-wide responsibility. Instead of limiting safety to select projects, SSA embeds it into every aspect of transportation planning and design.

At its core, SSA is grounded in six guiding principles that:

- Death and serious injury are unacceptable

- Humans make mistakes

- Humans are vulnerable

- Responsibility is shared

- Safety must be proactive

- Redundancy is crucial

These principles reflect a shift in how we understand transportation system. They establish that roadways must anticipate human error and be designed so those mistakes do not result in a death or a serious injury.

To put these principles into practice, SSA is organized around five key elements: Safer People, Safer Vehicles, Safer Speeds, Safer Roads, and Post-Crash Care. These elements function as an interconnected system. For example, infrastructure changes like raised intersections (Safer Roads) can encourage slower driving (Safer Speeds) while improving visibility for both drivers and pedestrians (Safer People).

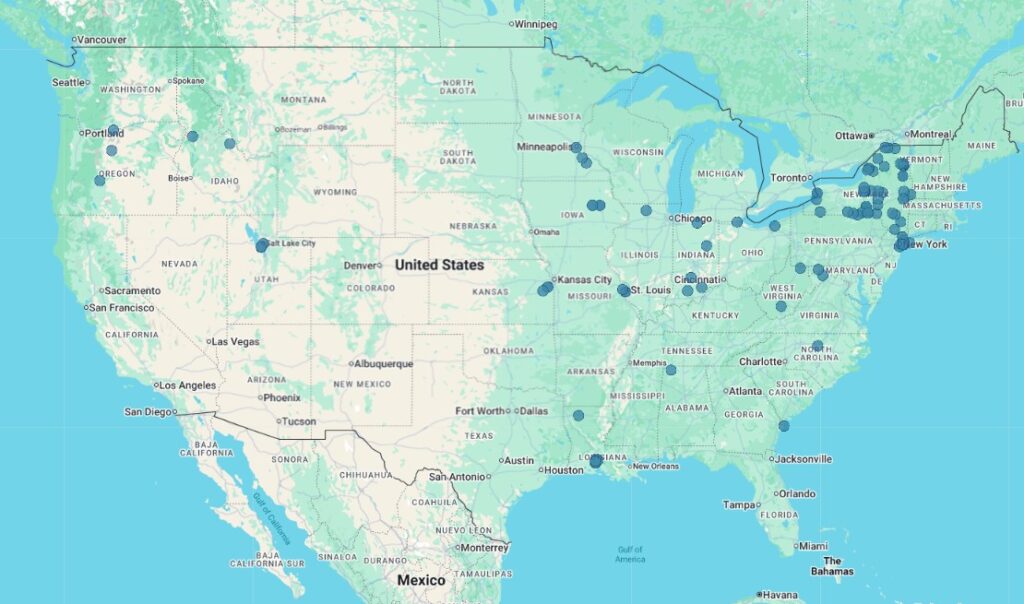

SSA has already shown success across cities and states nationwide. To learn how NJDOT is advancing this approach, we spoke with Jeevanjot Singh, Section Chief for Safety Programs Management within the Bureau of Safety Improvement Programs (BSIP). Our conversation covered the Route 129 project in Mercer County, NJDOT’s SSA training program, and the agency’s cross-department coordination to meet safety goals.

Q. The Safe System Approach is holistic and touches on many elements of a transportation system at once. How does NJDOT coordinate across departments to achieve SSA goals?

A. NJDOT’s adoption of the SSA reflects a strategic shift towards embedding safety as a core value across the organization. Our commissioner says it is the way of life, it’s not a campaign, a motto, or a logo. It’s not something you do today and forget tomorrow. This is how we operate at NJDOT.

This approach is holistic and not confined to a single unit. It requires a coordinated, agency-wide effort that aligns leadership priorities, operational practices, and resource allocation. To drive this transformation, NJDOT fosters cross-divisional and interdepartmental collaboration, with shared accountability integrated into every phase of project delivery, from planning to design, operations, and asset management.

For example, BSIP partners with planning when designing a project, and we remain involved throughout the construction. After a project is completed, we conduct a post-construction evaluation to identify areas for improvement. We also collaborate with the Intelligent Transportation System (ITS) team to determine how to incorporate technology to increase safety benefits.

Lastly, through the Strategic Highway Safety Plan (SHSP), we ensure that safety priorities are aligned across departments Statewide. This enables coordinated investment and policy decisions and helps leadership track progress towards statewide safety goals. NJDOT is cultivating a culture of safety through senior-level initiatives, training, and education, which empowers staff at all levels to understand their particular role in advancing safe system principles.

Q. One of the key principles of SSA is that responsibility is shared. How do you communicate that message effectively to different stakeholders—such as engineers, planners, law enforcement, and the public?

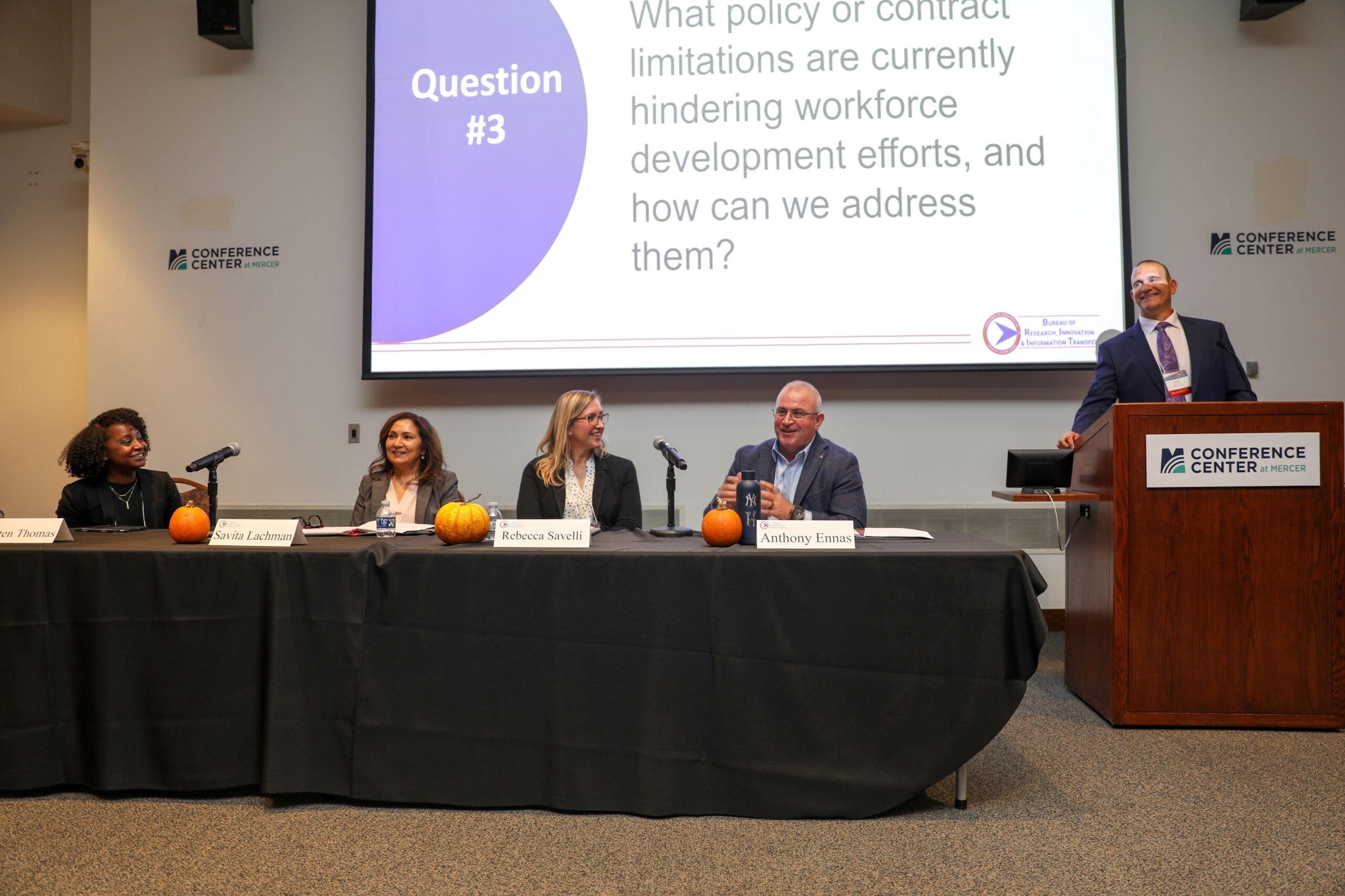

A. At NJDOT, we use the SHSP as a central platform to align stakeholders across engineering, planning, law enforcement, education, emergency response, governmental organizations, the private sector, and advocacy groups. The SHSP was developed collaboratively with representation from all of these groups on a stakeholder committee, sending a clear message that everyone has a role in eliminating traffic fatalities and serious injuries.

The SHSP reinforces the idea that achieving zero roadway deaths requires a coordinated, system-wide commitment. We advance this through annual stakeholder briefings, safety summits, and NJDOT-sponsored campaigns. We recently published several SSA videos on LinkedIn and YouTube, and we plan to continue engaging the public through these campaigns and will expand them in the future.

Doing this helps ensure transparency, helps people understand that safety is a shared responsibility, and allows us to share progress towards our safety goals, gather input, and reinforce safety as a shared mission.

Q. Some proponents of SSA have noted that, in certain cases, it is preferable to design a roadway that might see more crashes but fewer fatalities. Can you unpack that concept and explain how it might guide designs decisions?

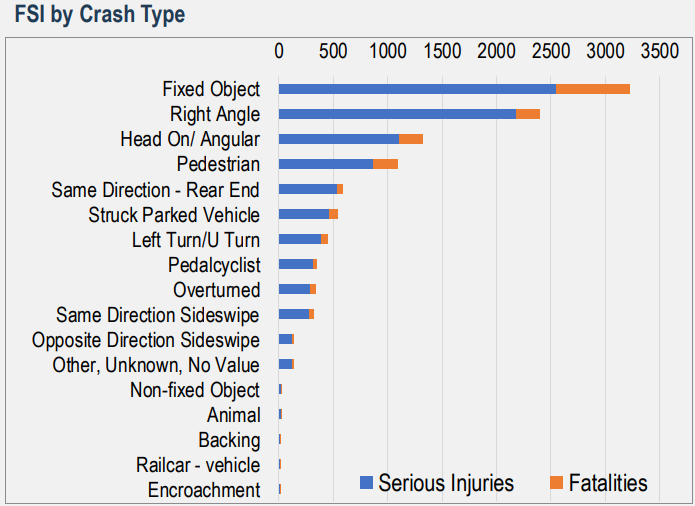

A. With the SSA, we need to rethink how we define success in roadway design. For example, a proven safety countermeasure is a roundabout. It may increase the rate of certain types of crashes like rear-ends or sideswipes, but significantly reduces severe crashes. These minor crashes occur at lower speeds, while higher severity crashes that can result in death or serious injury such as left turn or right-angle crashes are completely eliminated at a roundabout.

Historically, as reflected in the Highway Safety Manual, crash frequency and reducing total crashes was the major object of focus. But reducing the number of crashes does not necessarily reduce or eliminate higher severity crashes and road fatalities. One of the major shifts with the SSA is focusing on reducing the severity of crashes. We might see a slight increase in minor, low-impact crashes, but reducing significant injuries is the goal.

That is the ethical foundation of the SSA: no loss of life is acceptable. Humans will make mistakes, but the result of those mistakes should not lead to an empty seat at the dinner table. Our projects will increasingly prioritize speed management and reducing conflict points that lead to higher severity crashes. The SSA is a more ethical and human-centered approach to roadway safety.

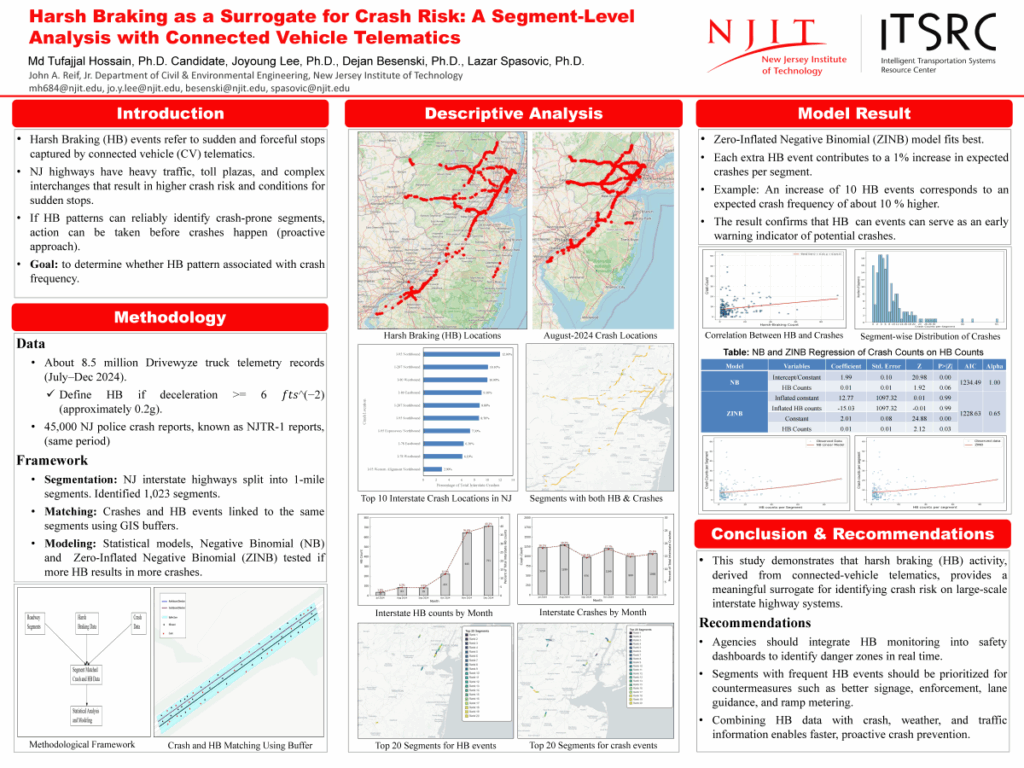

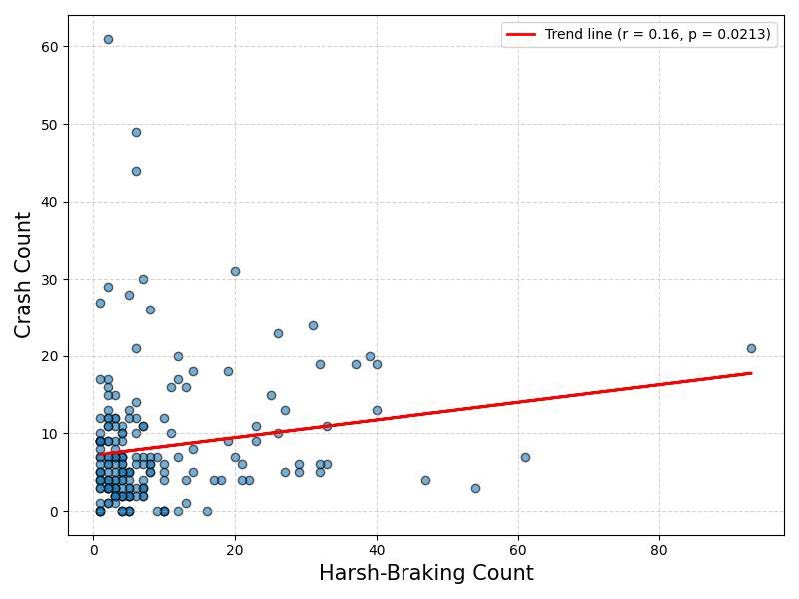

Q. When evaluating roads for safety improvements, how does NJDOT decide where to intervene? Do you focus primarily on areas with high crash rates, or do you also use proactive assessments of roadways to identify risks before crashes occur?

A. At NJDOT, we use both reactive and proactive data. Proactive analysis means conducting systemic, risk-based assessment, and reactive assessment relies on crash history to identify patterns. We combine historical data, hotspot analyses, and proactive risk assessments to align with the SSA.

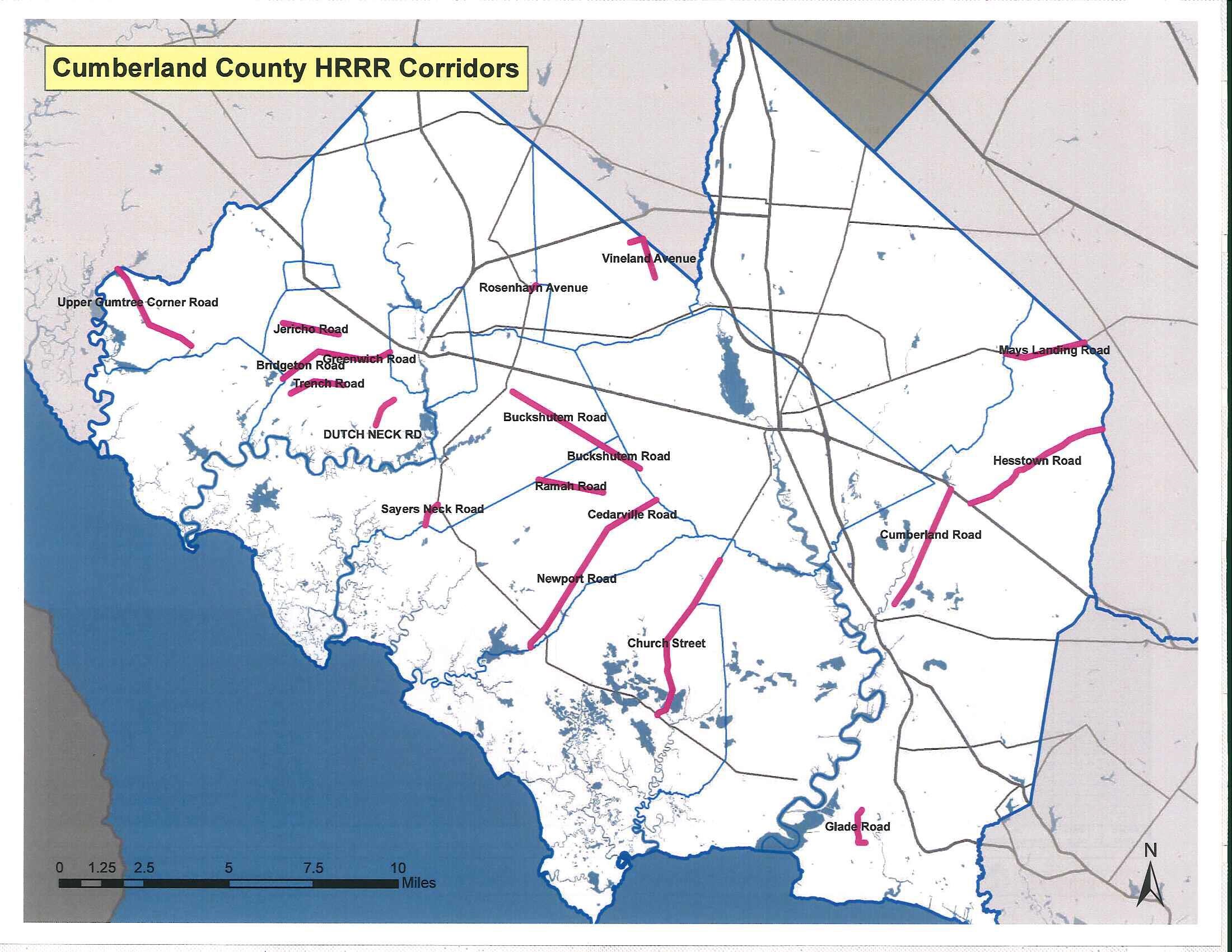

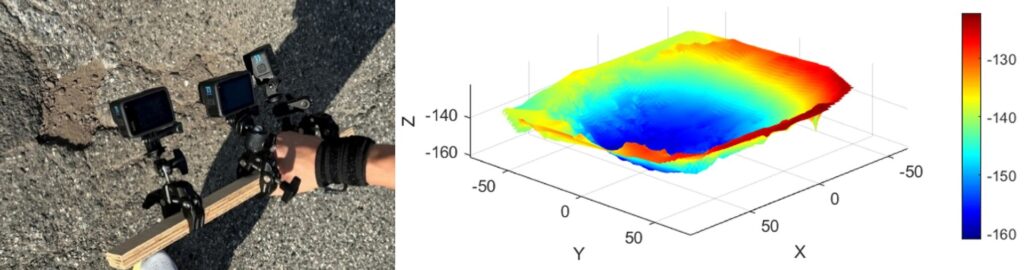

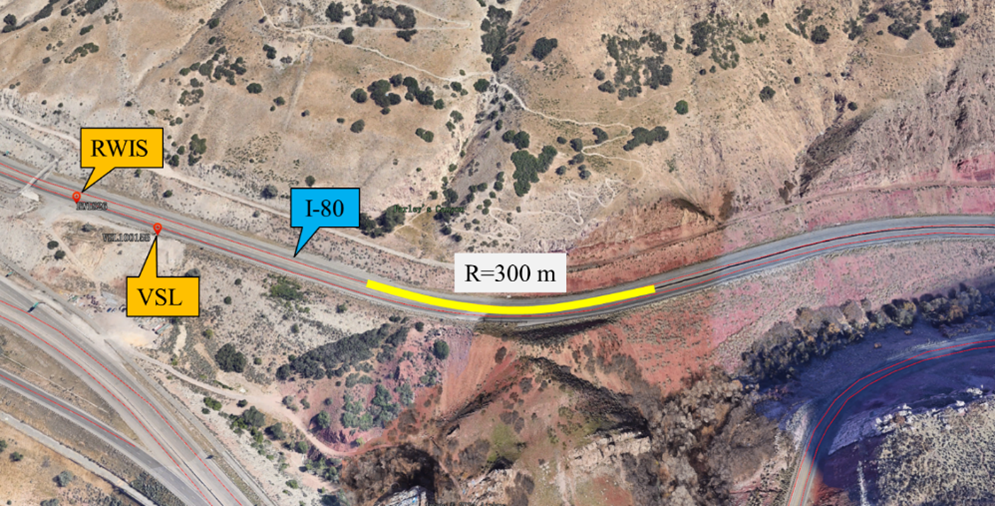

Traditionally, NJDOT relied heavily on crash data to identify hotspots locations with high crash frequencies or rates. This still plays a role, especially when there are urgent safety concerns. But we now also use systemic analysis. For example, we performed a horizontal curve analysis, where we looked at every horizontal curve in the state and local network and shared that data with the MPOs and counties. They are using it to improve some of the horizontal curves locally, and we have projects underway to improve those horizontal curves on the state network as well.

We now have several systemic analyses underway focused on wrong-way driving, intersections, school zones, pedestrians, and bicyclists. MPOs and local partners are developing their own roadway safety plans with similar proactive, systemic analyses to identify where certain crash risks may arise even before crashes occur.

In addition, we use systematic safety strategies by deploying proven safety countermeasures across the entire network, regardless of crash history. For example, we recently installed centerline rumble strips on all two-lane, undivided state roadways. We also have regional projects in design to improve pedestrian safety at every mid-block crossing on the state highway system. Another example is our Vegetation Safety Management Program, which systematically improves roadside clear zones and sight distance on our limited-access roadways and interstates.

Within the Highway Safety Improvement Program, we use both reactive and proactive methods, and we integrate safety into every capital project. For all projects, we provide safety management system data, share risk analysis findings, and encourage teams to address those risk.

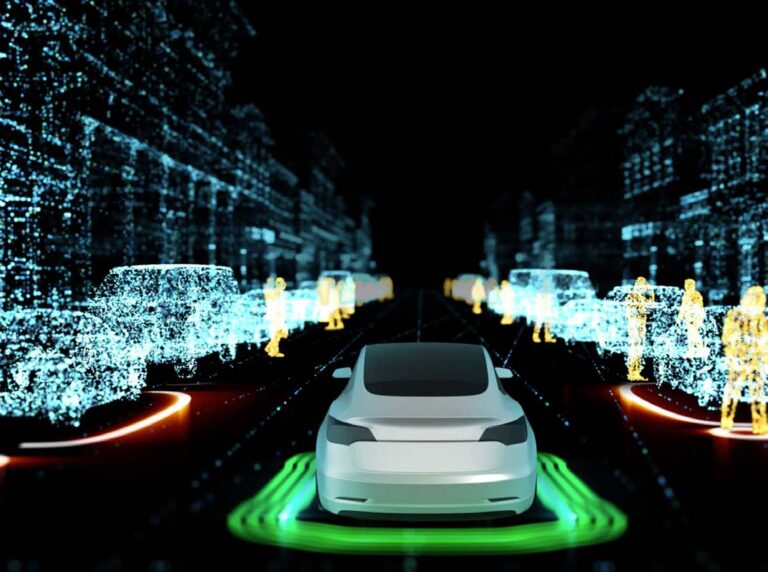

Q. One of SSA’s five elements is Safer Vehicles. Is NJDOT engaged in any initiatives that support safer vehicle technologies—such as automatic emergency braking, Vehicle to Everything (V2X) communication, or other automated innovations?

A. Vehicle manufacturers ultimately have the greatest influence over the technologies built into new vehicles, but we still play an important role through the SHSP. Two key strategies are education and fleet modernization.

First, we partner with agencies such as the New Jersey Division of Highway Traffic Safety, the New Jersey Motor Vehicle Commission, and AAA to educate drivers on how to use advanced safety features such as automated emergency braking and lane-keeping assist effectively and safely. We’ve found that many drivers disable certain safety features, so educating the public about what these systems are and why they matter is a major initiative.

Second, we support fleet modernization. NJDOT manages only a small portion of the state fleet, but we are reviewing procurement practices to ensure advanced safety technologies are considered whenever we replace vehicles at the end of their service life. This requires coordination with the Department of the Treasury to ensure procurement processes support these upgrades.

We are also advancing connected and autonomous vehicle (CAV) technologies. We are integrating CAV equipment into our ITS architecture to support vehicle-to-infrastructure and vehicle-to-everything communication. Most of our capital projects now include roadside units and other elements that enable V2X exchanges. We also recognize that CAVs require more than digital systems they need clear signage, consistent roadway geometry, and well-maintained pavement markings to accurately interpret their environment. These infrastructure elements are being prioritized to support safe and reliable automated vehicle operations.

Q. At the December 2024 NJSTIC Meeting, you mentioned NJDOT’s new SSA training program. What is the scope and goal of this training? Is this ongoing, and have any training sessions been delivered so far?

A. When we first heard about the SSA at the federal level, we conducted a gap analysis of what NJDOT is doing today in terms of safety and where we need to take it. Based on that analysis, we developed a New Jersey-based SSA training. The goal is to ensure that staff understand how SSA principles apply to their work.

It is a full-day interactive session introducing participants to the fundamentals of SSA. The course sparks discussion, encourages cross-disciplinary thinking, and builds a common language around safety.

We launched this program in December 2024 with a pilot of 30 participants from across NJDOT and partner agencies. We held a second session in October 2025 with more than 80 participants, and these sessions have built momentum for an effective integration of SSA.

Building on this success, we are developing a multi-day training session called SSA in Action, which will delve deeper into applying SSA principles to real-world projects, enabling staff to translate theory into practice. Eventually, we hope to open the training to consultants as well.

Q. Can you describe the Route 129 project in Mercer County? What SSA solutions are being applied there, and why was this corridor selected for the pilot?

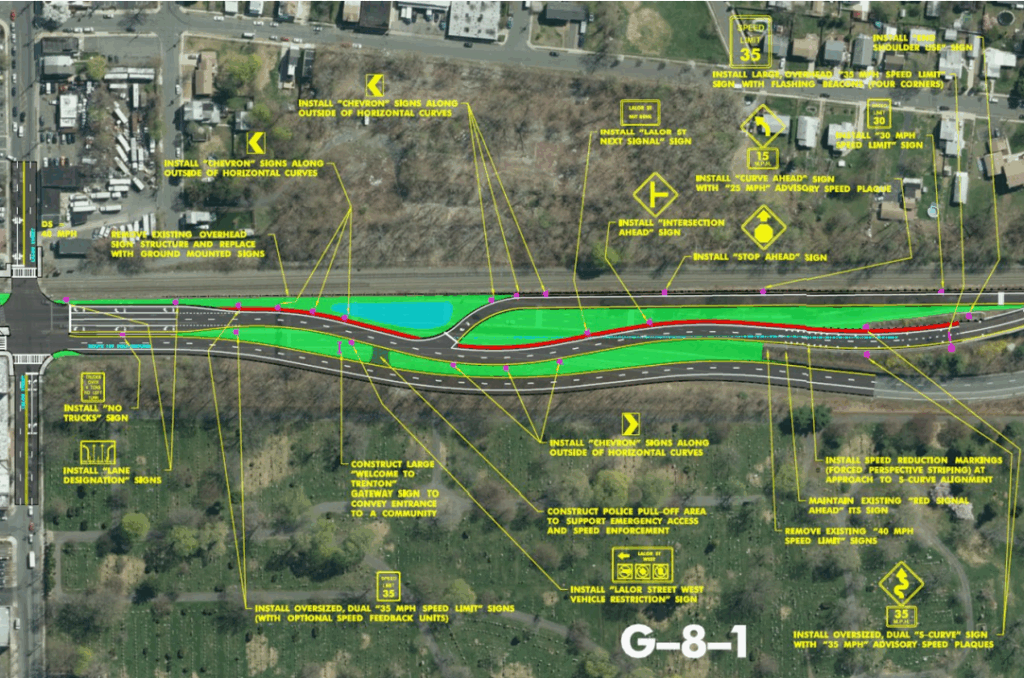

A. The Delaware Valley Regional Planning Commission and the City of Trenton conducted a road safety audit along Route 129 in 2020, which identified critical issues at multiple key intersections. We tried implementing improvements at targeted intersections along the corridor, but they did not produce sufficient results. So we decided to invest in corridor-wide safety improvements.

The corridor-wide design is structured around three major improvement categories: gateway improvements, corridor enhancements, and intersection upgrades. The categories align with the SSA roadway design hierarchy, which prioritizes strategies based on their potential to save lives.

- Tier 1: Remove severe conflicts. We are using a two-way shared-use path to physically separate pedestrians and bicyclists from vehicle traffic.

- Tier 2: Manage or reduce speeds. The corridor currently has a 45 mph with a 50 mph design speed. We are designing a serpentine gateway treatment with a target speed of 35mph and posted speeds of 30 mph to slow entering vehicles the corridor.

- Tier 3: Manage conflicts in time. The redesign includes right-turn-on-red restrictions at three intersections, leading pedestrian intervals, and Jersey Extension technology, which can automatically extend the all-red clearance if a pedestrian is still in the crosswalk or if a vehicle appears likely to run the red light, preventing a potential conflict.

- Tier 4: Increase attentiveness and awareness. We are adding enhanced pavement markings, transverse rumble strips, and advanced warning signs that will alert drivers to the changing environment.

Route 129 was chosen because it offers a strong opportunity to apply SSA comprehensively. By designing the corridor as a model of successful SSA integration, we can replicate the approach on future projects, including those in highly complex urban settings.

Q. Beyond Route 129, are there other NJDOT projects or pilots that highlight how SSA principles are being applied?

A. Two examples come to mind. The first project is the Route 26 Pavement Resurfacing Project on Livingston Avenue in Middlesex County. It was originally scoped as a standard mill-and-overlay. During discussions, the manager saw an opportunity to improve safety for the many cyclists and pedestrians who use this corridor. Even though the construction had begun, the manager issued a change order to add bike lanes, upgrade traffic signals, and enhance crosswalk visibility. This reflected SSA in action, prioritizing human life and adapting designs to better protect vulnerable road users.

The second example is a pavement preservation project on I-195 around exits 16A/16B near Six Flags and the outlet malls. The project manager asked our bureau key safety concerns at these exits, and we confirmed long-standing fixed-object crashes caused by confusion between the two exits. We updated the design with enhanced pavement markings and improved signage to reduce confusion and mitigate crash risks. This reflects another SSA principle: designing for human error and vulnerability. We anticipate mistakes will occur, and we used Tier 4 strategies to minimize confusion along this corridor.

These examples show that the SSA is not just for major redesigns as in the case of Route 129, small fixes on everyday projects can also prevent serious injuries and fatalities. We are empowering staff to recognize that making a corridor safer does not always require a huge effort.

Q. What do you see as the biggest challenges to fully adopting the Safe System Approach in New Jersey, and how is NJDOT working to overcome them?

A. One of the biggest challenges is shifting the cultural mindset from focusing on crash frequency to prioritizing reducing crash severity, and embracing the idea that no loss of life is acceptable. Making this shift requires changes in infrastructure design, policy, institutional practices, and public behavior.

Accepting human error is important. Mistakes such as distracted or impaired driving remain leading causes of crashes. The SSA does not ignore this reality. We must accept that errors will occur and design a system that is forgiving and prevents them from being fatal.

At NJDOT, we’re incorporating SSA principles strategically and incrementally improving our processes. We are prioritizing projects at high-risk locations and trying to embed SSA principles into all phase of project delivery. We want these examples to become the norm.

We also recognize that safety improvements must extend beyond state roadways. For example, we funded the South Jersey Transportation Planning Organization through the Highway Safety Improvement Program to support local road safety plans.

Ultimately, we’re targeting longer-term transformation, which requires shared commitment across agencies and communities. Our goal is to make the Bureau of Safety redundant. We want everyone at NJDOT to be a safety SME. We have already seen a major cultural shift under our former commissioners Diane Gutierrez-Scaccetti and Fran O’Connor, both of whom have been instrumental in advancing this safety culture change.

Q. How will NJDOT measure progress toward its goal of zero roadway deaths by 2040? Are there specific metrics or milestones you are tracking?

A. Measuring progress towards zero roadway deaths by 2040 requires a data-driven, transparent, and collaborative approach. We track key performance indicators such as the number and the rate of fatalities, the number and rate of serious injuries, and fatal and serious injury crashes involving non-motorized users. These metrics are updated annually using crash records and data from New Jersey’s Safety Management System, the State Police Traffic Fatalities Dashboard, the federal Fatality Analysis Reporting System database, and other reliable sources. We report these data in our annual safety report.

Beyond these numbers, the Target Zero Commission is developing a comprehensive action plan and a publicly accessible crash data portal, which will include a high-injury network to help identify and prioritize locations for safety improvements. The Commission will conduct periodic reviews and publish progress reports to ensure accountability. One requirement of the action plan requirements is identifying new metrics that we will track and report annually.

By combining robust data analysis with stakeholder input, NJDOT is working toward measurable and meaningful progress. These elements guide how we invest, shape policy, and ultimately save lives.