Dr. Thomas Bennert, of the Center for Advanced Infrastructure (CAIT) at Rutgers University, presented on Thursday, July 22, on his work leading the Pavement Support Program (PSP) for NJDOT’s Pavement & Drainage Management and Technology Unit. Dr. Bennert discussed in detail PSP’s current research and applications, explaining how a variety of innovative materials and technologies are being developed and applied to improve pavement performance across the state.

Dr. Bennert's talk provided an overview of the pavement program’s recent deliverables, as well as highlighted the future goals of the program. The PSP has several objectives and touches upon many disciplines from materials evaluation to supporting pavement management activities to addressing pavement design needs to assisting in training and workforce development. The PSP serves as an extension of the NJDOT workforce activities under the direction of the Pavement & Drainage Management and Technology Unit at NJDOT, which also helps to support the needs of the NJDOT Materials Bureau to inform materials characterization for more accurate pavement design and evaluation.

Since 2006, the PSP has assisted NJDOT through research and technical assistance related to pavement performance. Because of this continual, fifteen-year operation, data is available today that demonstrates the positive effects of the program’s work, such as how various asphalt composites have performed over time in comparison to traditional asphalt mixes.

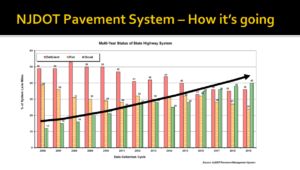

Data indicates a steady upward trend in the condition of New Jersey’s highway pavement, due to the sustained implementation of PSP’s research and deployment of various pavement preservation treatments

Dr. Bennert organized his talk by the seven major support tasks of the PSP, highlighting the purpose, examples and upcoming activities for each task. For the program’s first task, Innovative Materials, the program has focused on the development and improvement of specifications for roadway pavements, such as asphalt and concrete, to extend the life of the pavement. High Performance Thin Overlay (HPTO) was one of several examples whose purpose, design attributes and benefits were discussed. This pavement treatment improves rut and crack resistance, and extends the life expectancy of some pavements by over five years.

Dr. Bennert also touched on the rationale and challenges of applying another materials innovation, High Friction Surface Treatment (HFST), which was promoted as an FHWA Every Day Counts (EDC) initiative in 2015. While horizontal curves make up only 5 percent of U.S. roadways, more than 25 percent of total roadway fatalities occur on these sections. One way to increase friction in these areas is to apply an HFST, though the pavement must be in good condition. In New Jersey, rapid temperature swings can affect the epoxy on degraded asphalt, creating shallow potholes. To counter this failure, Dr. Bennert and his team have developed both a pre-screening protocol to determine whether a curve is suited for HFST, and a different adhesive more suited to asphalt.

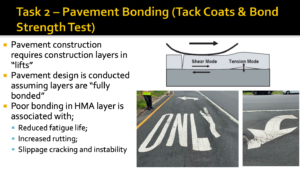

PSP is also tasked with researching innovative practices and technologies to improve the efficacy of the paving process. One example that Dr. Bennert shared involved researching ways to improve the pavement bonding. Two common problems are slippage, where the top layer does not adhere properly and begins to slide away, and more widespread tension issues, in which failure to bond causes uneven loads, warping the pavement. To avoid premature failure, the program has developed performance-based specifications for tack coats (the term for the adhesive layer between tiers of asphalt), a testing mechanism to better understand the properties of tack coats, and new criteria for construction practices to ensure that pavement is put together properly.

The PSP includes a pavement management system support task to assist NJDOT in the collection of data, the management and quality control of data, and the application of data to inform decision-making priorities. For example, the NJDOT Pavement Management group conducts yearly pavement condition assessments to help forecast needs of pavement activities and funding allocations to optimize budgetary resources for pavement preservation and larger rehabilitation and reconstruction projects. This process uses Pavement Management Systems (PMS) condition and program mapping, and future work is expected to continue to incorporate GIS mapping models to create an even more comprehensive picture.

Until recently, the status of the state’s many miles of pavement has been historically performed using an employee’s vision and judgment. Instead, PSP is looking to deploy cameras and computer-based processing power along roadways to automate data collection for developing surface distress index ratings, and even to calibrate and predict the infrastructure’s future performance to inform Pavement Design.

New methods in data collection and mapping allow for a more comprehensive picture of pavement conditions across the state

Finally, PSP engages in policy analysis, develops white papers on current and emerging practices, and provides technology transfer and trainings for NJDOT. Such work includes Cost Benefit Analyses (CBAs) to determine the cost effectiveness of new materials, tackling the question of whether the additional costs to manufacture can be justified by the additional years added to the roadway’s life cycle. Dr. Bennert shared slides showing how CBAs of HPTO and several other hybrid asphalt mixes had higher Benefit/Cost Ratios than traditional Hot Mix Asphalt (HMA). The program engages in trainings and presentations with NJDOT regularly, presenting on research and technological innovations, and facilitating technology transfer and continuity for newer staff.

Dr. Bennert concluded his presentation by commending NJDOT as a national leader in performance testing for asphalt and handling of composite pavements. The Pavement Support Program will continue to address the immediate needs of the Pavement & Drainage Management and Technology Unit at NJDOT, sustaining their research, development, and implementation of cutting-edge pavement technologies. “What we’re doing here is making a big impact in the state.” Dr. Bennert said.

Afterward, Dr. Bennert answered audience questions in a brief Q&A.

Q. How does New Jersey compare to other states in our use of high performance thin overlay (HPTO)?

Dr. Bennert: We’re working with FHWA on the EDC-6 rollout of HPTO. We use it significantly more than most states, besides Texas. New Jersey is a leader on performance testing in general.

Q. How widespread is the use of the High Friction Surface Treatment (HFST) in New Jersey?

Dr. Bennert: While I don’t have the crash reduction data, I do know that it’s been used successfully by the state and some municipalities as well. As shown earlier, there have been some failures with the technology’s application, which we are now working to identify the reasons for failure and reduce through our research.

Q. As reported in the HFST guidelines, why do you think an early drop in skid resistance was observed in the treatment’s application, despite the very hard aggregate that was used?

Dr. Bennert: Simply, it is due to the material loosening in the epoxy. The embedment depth of that aggregate is very important. If it’s too deep, the aggregate is almost drowning in the epoxy, and if it too shallow, it can pull out very easily as vehicles travel over it. The recommendation is to monitor the HFST over the first few years. Because HFST has a limited shelf-life, monitoring friction is very important.

Q. How many sub-consultants do you have on this project, and which private consultants are contracted as sub-consultants?

Dr. Bennert: Currently, the only group that we have working with us on the contract this year is the company that manufactures the software for the pavement management system. This can change based on the needs of Pavement & Drainage Management and Technology Unit at NJDOT.

Q. Could you speak on pavement mix testing for future climate concerns?

Dr. Bennert: We have tests and thresholds for how the material should be performing, and additional heat will often stiffen the material a bit more, which can further age the pavement. We could get some increased, accelerated stiffening. PSP has been working with NJDOT on test methods to identify appropriate asphalt materials and test methods to help identify materials that are prone to aging, which could be especially useful to address climate concerns.

Q. What is the future of Cold Mix Asphalt and its potential use on heavily truck trafficked New Jersey highways?

Dr. Bennert: In New Jersey, we don’t have low volume roads where we could put material out without an overlay. Without some kind of confinement, the material could easily break apart. I’m looking forward to the rollout of central plant technology, which will allow us to take material from a project and put that back, an almost 100 percent recycling of the material for a project’s base application. This would be a base application to help reduce the recycled asphalt pavement stockpiles in the state.

Q. Did you test Ultra-Thin Friction Course and how does it compare to High Performance Thin Overlay?

Dr. Bennert: Ultra-Thin Friction Course can be thought of as a treatment option between an Open-Graded Friction Course and a Chip Seal. It’s used more for pavement preservation, rather than structure, but it does a good job at sealing off the pavement. The High Performance Thin Overlay is thicker, and helps to provide structural integrity of the pavement, both sealing it and adding rutting and cracking resistance. There’s a difference in the thickness of the materials, and the targeted applications.

A recording of the webinar is available here, (or to the right).

Dr. Bennert’s presentation can be found here.

Resources

Federal Highway Administration. Targeted Overlay Pavement Solutions. https://www.fhwa.dot.gov/innovation/everydaycounts/edc_6/targeted_overlay_pavement.cfm

Bennert T. and D. Pezeshki. (2015). Performance Testing for HMA Quality Assurance. Report, Rutgers, Center for Advanced Infrastructure and Technology. FHWA-NJ-2015-010. https://cait.rutgers.edu/wp-content/uploads/2018/05/fhwa-nj-2015-010.pdf

NJDOT Technology Transfer. Pavement Preservation at NJDOT. Video. https://www.youtube.com/watch?v=n1wlnB8AQ-g&t=128s