During Every Day Counts round (EDC-6), FHWA promoted Targeted Overlay Pavement Solutions (TOPS) to state departments of transportation (DOTs) and local agencies as a way to maximize their highway repair investments by improving on conventional overlay methods and including new overlay materials and techniques. Case studies and research presented as part of FHWA’s EDC outreach efforts to states and local agencies included New Jersey DOT’s use of highly modified asphalt (HiMA), among other proven but underutilized overlay options.

In a recent Innovator Newsletter, FHWA highlighted NJDOT’s use of HiMA to effectively improve the quality and extend the lifespan of roadways.

Overview

NJDOT’s use of HiMA was the subject of a detailed technical case study, one of five such case studies focused on Targeted Overlay Pavement Solutions (TOPS) produced for the FHWA. The case study report, High Performance Thin Overlays (HPTPO), notes that NJDOT has increasingly been using HPTO mixes for preventive maintenance projects statewide.

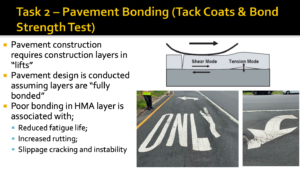

The case study shares NJDOT’s experience leading a team of design engineers, materials engineers, researchers and asphalt suppliers to devise and evaluate HPTO, a gap-graded mixture using polymer-modified asphalt binder. The case study offers incisive details and lessons learned on specifications, implementation, design, planning, construction, and performance considerations.

The case study explains that NJDOT defines HPTO as a fine-graded polymer-modified asphalt mixture that uses 100 percent high-quality crushed stone with a nominal maximum aggregate size of 3/8 inch. HPTO is designed using a modified Superpave (Superior Performing Asphalt Pavement System) design methodology that places restrictions on the use of reclaimed asphalt pavement and natural sands.

HPTO mixes are typically used in maintenance and pavement preservation applications but can also be used as a leveling course when extended staging times are expected for temporary pavements during construction. HPTO, a durable mixture, is designed for high resistance to rutting and cracking and is often placed at a thickness of 1 inch either on a milled or unmilled surface. HPTO has been used as a maintenance application on high-volume interstate projects and on heavy-duty parking lots. The product is typically performance-tested at design and during construction.

NJDOT primarily uses HPTO as a preservation application on pavements in good to fair condition in need of minimal repairs (i.e., repairs account for less than 10 percent of the preservation project). However, HPTO can be combined with other preservation strategies such as microsurfacing, slurry seals, or micro-milling when project conditions warrant its use.

The FHWA case study report on NJDOT’s experience with HPTO offers several references that further detail various asphalt research studies, and analyses undertaken over more than a decade that advanced HPTO as product through testing, evaluation and institutionalization stages at NJDOT.

Lessons and Benefits

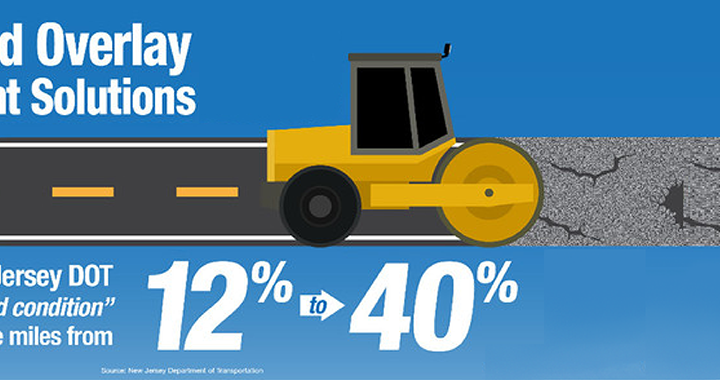

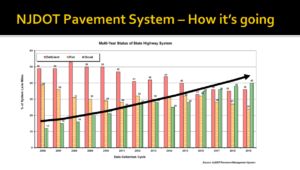

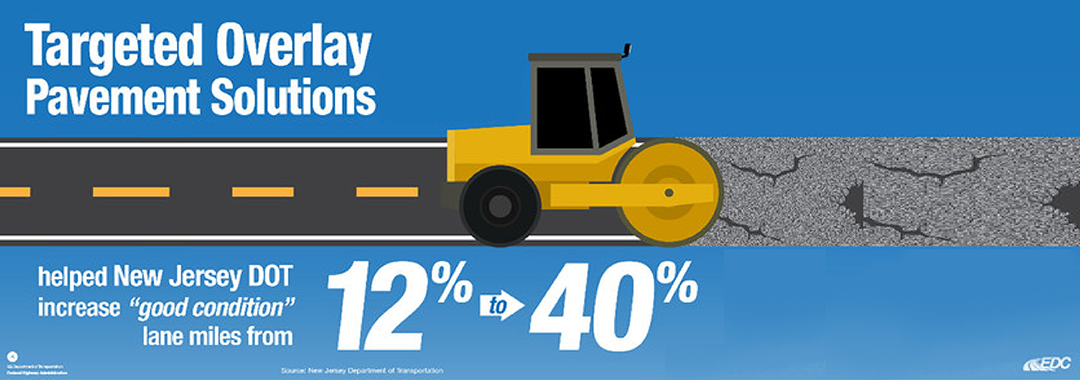

NJDOT adopted a proactive approach to advancing pavement preservation in its asset management toolbox, particularly through HiMA, that has delivered several noteworthy benefits. NJDOT was able to increase the percentage of its network pavements in “good condition” while reducing pavements in “poor condition” through dedicated program funding for preventive maintenance. FHWA noted that NJDOT was able to increase the number of “good condition” lane miles from 12 percent to 40 percent over a decade in part through the contribution of HiMA overlay treatments.

Through research, NJDOT found that the timing of HPTO application is crucial for getting the maximum pavement life extension. HPTO, when applied to an existing pavement in “good condition” can more than double the service life compared to its application to “fair condition” pavement.

Utilizing HPTO, NJDOT has been able to extend pavement life along busy roadways by approximately 10 years and improve ride quality — depending on the pre-existing surface conditions, quality of pre-HPTO repairs, and thickness of the HPTO overlay. HPTO can also reduce noise and improve long-term skid resistance on projects. During construction, HPTO’s application causes relatively minimal traffic disruption as it requires only short duration road closures.

HPTO also offers flexible solutions to NJDOT’s design concerns by adding service life to a pavement without a significant change in profile grade. It can minimize changes to the vertical clearance at overpasses and match the elevation of infrastructures such as guardrails, curbs, and gutters.

Ongoing Efforts to Support Implementation

For the FHWA, EDC-6 outreach activities served as an opportunity to educate transportation agencies and stakeholders about various asphalt and concrete overlay products that demonstrably provide long-life performance under a wide range of traffic, environmental, and existing pavement conditions. The EDC-6 TOPS team sought to build greater awareness and encourage deployment of some 7 distinct asphalt products and 4 distinct concrete products during the EDC-6 Round.

In its final report for EDC-6, FHWA notes that forty-one States participated in the TOPS EDC-6 initiative, including 26 that were focused on asphalt overlays, 15 that sought to learn more about concrete, and 13 that participated in both. Further, FHWA recognized that EDC-6 was also a catalyst for advancing deployment; 22 States advanced to a new phase in the implementation process from “not implementing” to the development, demonstration, assessment, or institutionalized phases of deployment. In all, 19 States reported that they had institutionalized TOPS products by incorporating at least one overlay type as a standard fix option within the agency’s pavement management program.

While the formal EDC-6 innovation cycle ended in December 2022, FHWA continues to support TOPS implementation through training and technical assistance resources such as the lessons learned from NJDOT’s use of HPTO as well as noteworthy initiatives in several other states. Many resources are available on the TOPS webpage including webinars, articles, case studies, how-to reports, brochures, and one-pagers.

Resources

U.S. Department of Transportation, Federal Highway Administration. “Innovative Solutions for America’s Roads: Targeted Overlay Pavement Solutions (TOPS)”. (October/November 2024). Innovator [Article]. Retrieved from: https://www.fhwa.dot.gov/innovation/innovator/issue103/page_03.html

U.S. Department of Transportation, Federal Highway Administration (u.d.). EDC-6: Targeted Overlay Pavement Solutions (TOPS). [Website]. Retrieved from: https://www.fhwa.dot.gov/pavement/tops/?utm_source=innovator

U.S. Department of Transportation, Federal Highway Administration. (April 2023). EDC-6 Final Report: Innovation for a Nation on the Move. Retrieved from: https://www.fhwa.dot.gov/innovation/everydaycounts/reports/edc6_finalreport.pdf?utm_source=innovator.

Gilliland, Amanda, Mohanraj, Kiran, and Taghavi Ghalesari Abbasali, Ph.D. (March 2022). High-Performance Thin Overlays. [Case Study Report]. FHWA-HIF-22-053. Retrieved from: https://www.fhwa.dot.gov/pavement/tops/pubs/TOPS_HPTO_Case_Study_Report_508.pdf.

Gilliland, Amanda, Mohanraj, Kiran, and Taghavi Ghalesari Abbasali, Ph.D. (April 2022). High-Performance Thin Overlays: How-To Document. [Case Study Report]. FHWA-HIF-22-057. Retrieved from: https://www.fhwa.dot.gov/pavement/tops/pubs/TOPS_HPTO_How_To_Report_508.pdf

NJDOT’s Pavement Support Program – Goals, Deliverables and the Future. (July 2021). NJDOT Technology Transfer. [Webinar]. Retrieved from: https://www.youtube.com/watch?v=EGhxphN1rOA&t=4057s.

NJDOT Pavement Preservation at NJDOT. (July 2020). NJDOT Technology Transfer. [Video]. https://www.youtube.com/watch?v=n1wlnB8AQ-g.