On August 27, 2025, the FHWA hosted a webinar titled “NJDOT’s Pilot Program for Internally Cured High Performance Concrete for Bridge Decks.” NJDOT Project Manager and Infrastructure Preservation CIA team lead Samer Rabie presented the department’s internally cured concrete (ICC) initiative.

The webinar highlighted NJDOT’s work as a case study for more than 300 participants nationwide, enabling agencies to learn from New Jersey’s experience with ICC and consider applications in their own states. After Mr. Rabie’s presentation, attendees asked questions about the EPIC2 initiative, including advice on how to achieve even water distribution, the expected life span of High Performance Internally Cured Concrete (HPIC) bridge decks, and whether internal curing techniques could be applied to other types of concrete.

Webinar Presentation

As part of Round 6 of the Every Day Counts (EDC) initiative, NJDOT began implementing Ultra High Performance Concrete (UHPC) for Bridge Preservation and Repair, with plans to institutionalize its use in the upcoming bridge design manual. UHPC’s low water-cement ratio and high use of supplementary cementitious materials (SCMs) increase durability and extend service life, but also raise the risk of transverse early age cracking. This cracking results from autogenous shrinkage, when the cement consumes too much internal water, creating capillary stresses.

Cracks in UHPC bridge decks require costly, time-intensive sealing that must be reapplied every five to ten years, significantly increasing life-cycle costs. To address this issue, FHWA launched the Enhancing Performance with Internally Cured Concrete (EPIC2) initiative under EDC-7. Internal curing uses pre-wetted lightweight fine aggregate (LWFA) to supply additional moisture, improving water distribution and offsetting capillary stresses during the curing process. More than 30 years of studies show that internal curing enhances durability, lowers costs, and reduces waste.

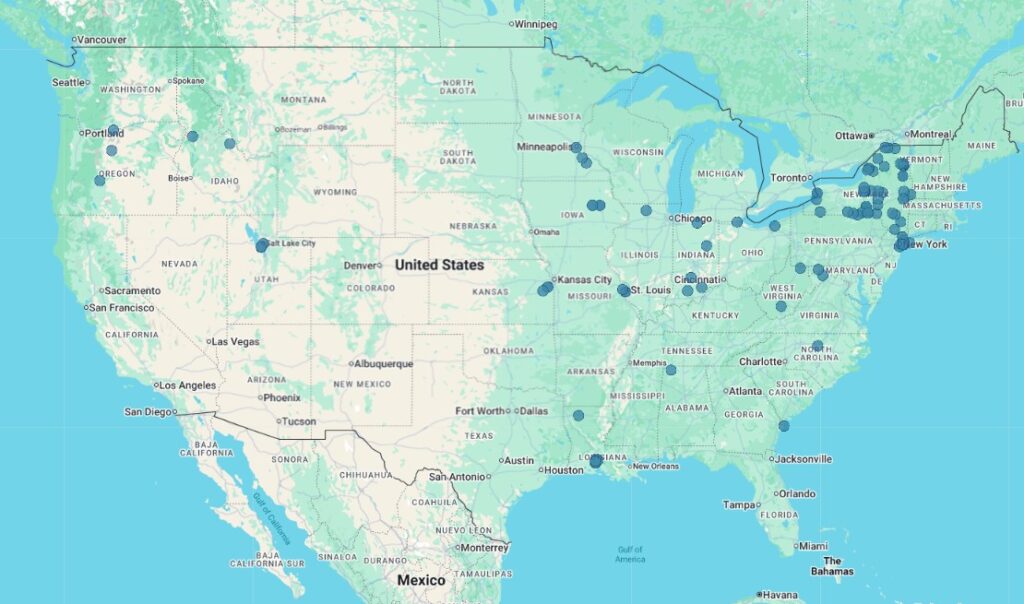

To date, more than 15 states have deployed internal curing on over 180 bridge decks. NYSDOT, an early adopter of HPIC, reported a 70 percent reduction in early-age cracking with no added cost compared to conventional HPC or UHPC decks. NYSDOT has since mandated internal curing for all continuous bridges and bridge decks statewide. In May 2024, Mr. Rabie participated in a New York State peer exchange on the EPIC2 initiative in Albany.

NJDOT launched its HPIC implementation plan by reviewing existing research, assessing resources and mix plants, and conducting extensive coordination—internally with subject matter experts and divisions, and externally with LWFA suppliers, producers, and contractors. NJDOT also conducted risk evaluations and identified candidate bridges for potential pilot projects.

To support implementation, NJDOT secured a $125,000 STIC Incentive Grant, which funded the purchase of centrifuge apparatuses, staff training, and third-party lab support. The centrifuges measure LWFA moisture content, replacing the traditional “paper towel method,” in which pre-wetted aggregate is weighed, dried manually with industrial-grade paper towels until no moisture remains, and then oven-dried before an assessment is made of surface and absorbed moisture. While the centrifuge approach requires specialized equipment and training, it is significantly faster, less labor-intensive, and more accurate. NJDOT will phase in this method as staff gain experience.

NJDOT has identified 11 candidate bridges for HPIC pilot projects: one under construction, eight in design, and two in concept development. The active pilot—North Munn Avenue over I-280 in East Orange—features twin bridge decks, one built with UHPC and the other with HPIC, enabling a direct comparison under similar conditions.

Alongside pilot projects, NJDOT is developing materials and construction guide specifications for HPIC. These include substituting 30–50 percent of total fine aggregate with LWFA, establishing a formula to measure absorbed LWFA moisture, and targeting a water content equal to 7 percent of the volume of cementitious materials. Aside from these adjustments, HPIC batching mirrors current UHPC practices.

Early HPIC bridge decks are expected to carry added upfront costs: approximately $50,000 for new mix design, trial batches, and test slabs to validate the process before construction, plus a 20–40 percent increase in unit production costs. Mr. Rabie noted that costs should decrease as specifications are refined, experience grows, and economies of scale take effect. While initial expenses may be higher, HPIC is projected to deliver substantially lower life-cycle costs, primarily by reducing resealing, which can cost around $100,000.

NJDOT’s next steps include a concrete plant outreach program in fall 2025, followed by HPIC workshops and centrifuge training in winter 2025/2026. The department will also continue to assess potential pilot projects through 2025–2026 and monitor the performance of active HPIC bridge deck projects.

Q&A

Q. Will HPIC extend the expected 25-year life span of a bridge deck?

A. The study is assessing how much maintenance HPIC bridge decks require over a 25-year lifespan. Preliminary findings suggest HPIC decks may require only about one-third the maintenance of conventional decks. NJDOT’s Bureau of Research, Innovation, and Information Transfer (BRIIT), in partnership with Rutgers University, is conducting a separate study evaluating how HPIC could extend overall service life. Early findings from NYSDOT suggest HPIC bridge decks may last up to 75 years.

Q. In South Carolina, we have faced difficulties achieving a uniform distribution of moisture for our pre-wetted lightweight fine aggregate using conventional methods like sprinklers. Do you have any suggestions on ways to fix this issue?

A. Some states have tried alternative methods for wetting LWFA. In Louisiana, for example, large bins are filled with water—like a small pool—and the aggregate is soaked for a set period to ensure uniform moisture distribution, rather than using sprinklers.

Q. Can internal curing be used on conventional concrete or is it just for HPC and UHPC?

A. Internal curing could technically be applied to conventional Class A concrete, but it is generally unnecessary. Class A concrete already contains higher water content, reducing its susceptibility to autogenous cracking. UHPC, being relatively moisture starved, benefits most from internal curing.

Q. Does NJDOT have set shrinkage limits?

A. Shrinkage is assessed project-by-project. After crack mapping is completed, a percentage of shrinkage is calculated, but there is no set limit.

A recording of the FHWA webinar is available here.

For more about HPIC and EPIC2, read the NJDOT Tech Transfer Q&A article with Samer Rabie and Jess Mendenhall.