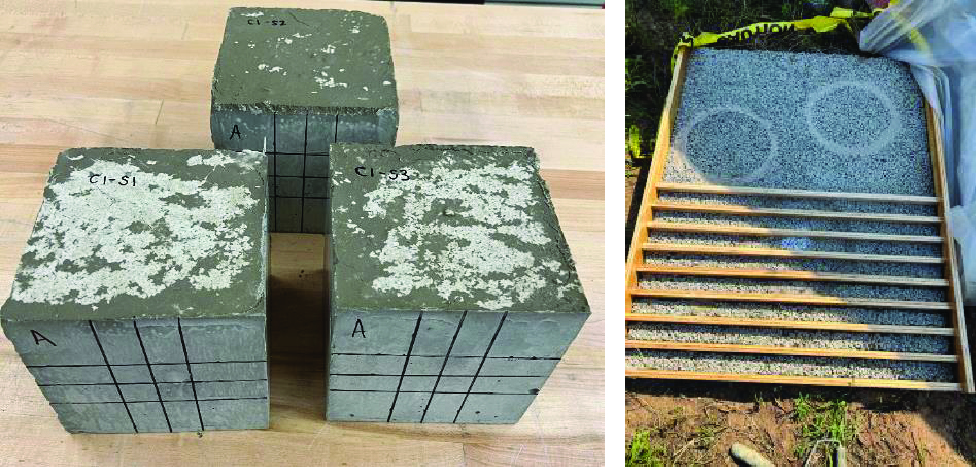

Long lasting and durable repair materials are necessary for maintaining concrete pavements, concrete bridge decks, and substructure to prevent deterioration and ensure longer service life. Rapid setting cementitious patch repair materials are popular for repairing small concrete damages and providing a functional repair within few hours. Based on extensive literature search and several DOT practices, three formulations were chosen as the best performing candidates. All three formulations are listed on the NJDOT QPL. The three formulations were further improved to increase workability especially for pumping, better toughness, and better adhesion to eliminate the need for the bedding compound. The workability was improved using the polymer whereas the toughness using nonmetallic fibers. One formulation has a stronger adhesion which could be used where adhesion is a primary requirement. Typically the repair mortar has a lower shrinkage strains. An attempt was made to further decrease the shrinkage strains by adding fine aggregates. Workability, strength, and restrained shrinkage cracking of the formulations were investigated The restraint shrinkage test protocol simulated upper and lower limits of restraint that a repair material undergoes in real applications. The repairs were also cast and placed in external environmental conditions to expose them to natural weathering actions. The cracking behavior was evaluated including cracking spacing and maximum crack width. The investigation led to the identification of three formulations that did not crack for a period of 10 months in filed exposure to NJ climate conditions. Typically rapid set formulations do not shrink after 6 months. The formulations that did crack revealed that addition of 1 percent of PVA fibers could significantly reduce the maximum crack width. The maximum crack widths observed in all the formulations were an order of magnitude less than the maximum allowable crack width specified by NJDOT which is 1/32 in. Use of Schmidt hammer for non-destructive compression testing of rapid setting class of materials was evaluated so it can be used as quality assurance tool before openings lanes to traffic. The research effort did lead to the identifications of the formulations for horizontal, vertical, and overhead rapid repairs and elimination of the bedding compound. The Schmidt hammer can be used to ascertain that the needed compressive strength was achieved.NJDOT Research

Posted in Uncategorized.