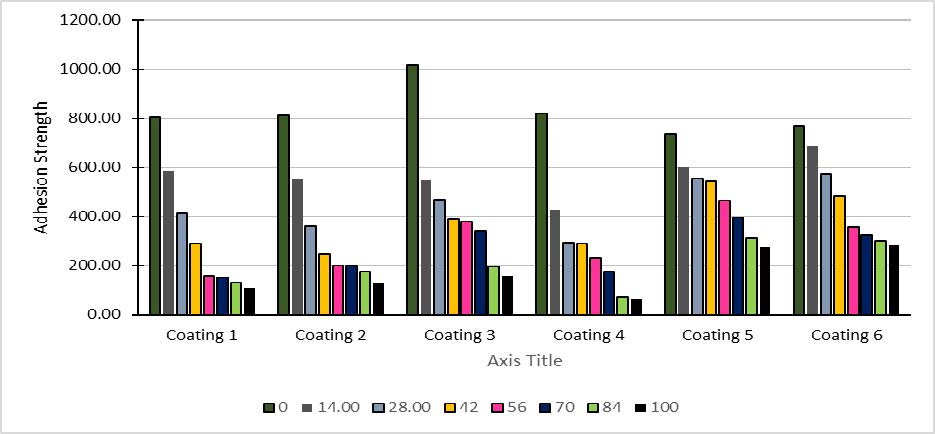

The project was undertaken to identify a procedure to accept new coating systems for over-coating of steel surfaces. The practices used by various state transportation agencies, and test methods for accelerated testing of coatings with primary focus on ASTM and FHWA guidelines were reviewed. It was concluded that a new protocol for accepting new systems that will provide results in a timely manner is required. Therefore, a new protocol for evaluating durability of coatings and their effectiveness in reducing corrosion of steel structures was developed. Results presented in this report focus on the details of the new protocol, recommendations for acceptance and a plan for implementation. Basic parameters of relevant ASTM specifications and guidelines provided in FHWA publications are incorporated in the test method. The major difference between the proposed method and the current practice is the way the corrosion creep from a coating-damaged location is measured after exposure to accelerated corrosive conditions. The proposed method is based on direct pull-off (adhesion) strength at various stages of corrosion. These pull-off strengths provide quantitative and repeatable measurements for quantifying the degradation. In the area of accelerated exposure conditions, deep freezing is incorporated as part of the accelerated degradation process. These two measures provide significant and clearly measurable degradation within three months of accelerated exposure. Coatings that are known to provide excellent and weak corrosion protection were tested using the proposed protocol and the results show a clear difference between the best and the poor coatings. The test results also correlate well with results of the long-term field study. As expected, corrosion creep from a damaged-coating location is the primary contributor to degradation of coatings. Other degradation indicators such as thinning, color change, influence of welding and bolt hole locations were also evaluated. Acceptance criteria for these degradation mechanisms are also incorporated in the acceptance criteria. In the area of quality assurance, this study evaluates correlation coefficients for structural steel paints by performing Infra-Red (IR) scan using ASTM specifications E 2937. Chemical signatures have been established for the components of six coating systems that are currently approved for use by New Jersey Department of Transportation (NJDOT).NJDOT Research

Posted in Uncategorized.